Cáp Điều Khiển Sang jin ( 60227 KS IEC 52/53/56/57 ) 300/500V PVC/PVC Flexible Circular Cords (70℃) (90℃)

60227 KS IEC (VCTF) _ KS C IEC 60227-5

300/500V비닐시스원형코드/ 300/500V PVC/PVC Flexible Circular Cords

�적용범위

주로옥내에서AC 300/500V 이하의 전기, 전자, 음향기기,

조명기기등 소형전기 기구에사용.

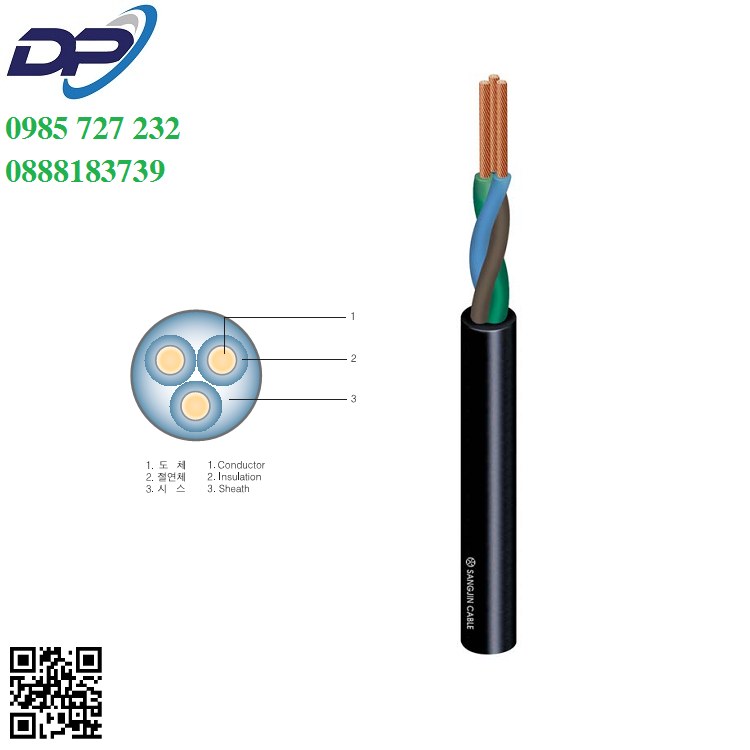

�구 조

1. 도체: 5등급(집∙복합연선) 연동선

2. 절연체: PVC (70℃∙90℃)

3. 시스: PVC (70℃∙90℃)

�선심식별

선심수 색

1심 흑색

2심 하늘색,갈색

3심 녹/황, 하늘색,갈색또는하늘색,흑색,갈색

4심 녹/황, 하늘색,흑색,갈색또는하늘색,흑색,

갈색,흑색또는갈색

5심 녹/황, 하늘색,흑색,갈색,흑색혹은 갈색또는

하늘색,흑색,흑갈색혹은 갈색,흑색혹은 갈색

�최고허용온도: 70℃, 90℃

�적용규격: KS C IEC60227-5 / 전기용품안전기준(K 60227-5)

�제품인증

한국산업규격

전기용품안전인증

�종류및기호

60227 KS IEC 52 (VCTF) 연질비닐시스코드(70℃)

60227 KS IEC 53 (VCTF) 범용비닐시스코드(70℃)

60227 KS IEC 56 (H-VCTF)내열성연질비닐시스코드(90℃)

60227 KS IEC 57 (H-VCTF)내열성범용비닐시스코드(90℃)

�APPLICATION

This cords is widely used in electrical, electron, sound, lighting etc. electrical

home apparatus under AC 300/500V.

�CONSTRUCTION

1. Conductor : Flexible Stranded Annealed Copper (Class 5)

2. Insulation : PVC (Poly Vinyl Chloride, 70℃∙90℃)

3. Sheath : PVC (Poly Vinyl Chloride, 70℃∙90℃)

The sheath may fill the interstices between the cores but it shall

not adhere to the cores

�CORE IDENTIFICATION

No. of Cores Color

1 core Black

2 core Sky Blue, Brown

3 core Green/Yellow, Sky Blue, Brown or Sky Blue, Black, Brown,

4 core Green/Yellow, Sky Blue, Black, Brown or sky Blue, Black, Brown, Black or Brown

5 core Green/Yellow, Sky Blue, Black, Brown, Black or Brown or Sky Blue, Black, Dark Brown or Brown, Black or Brown

�MAXIMUM ALLOWABLE TEMPERATURE : 70℃, 90℃

�STANDARD : KS C IEC 60227-5

�CERTIFICATE

Korean Industrial Standards

Safety Certification for Electric and Electronic Appliance

�CLASSES AND SYMBOLS

60227 KS IEC 52 300/300V Light Poly vinyl Chloride Sheathed Flexible Circular Cord (70℃)

60227 KS IEC 53 300/500V Ordinary Poly vinyl Chloride Sheathed Flexible Circular Cord (70℃)

60227 KS IEC 56 300/300V Heat-Resistant Light Poly vinyl Chloride Sheathed Flexible Circular Cord (90℃)

60227 KS IEC 57 300/500V Heat-Resistant Ordinary Poly vinyl Chloride Sheathed Flexible Circular Cord (90℃)

VCTF/H-VCTF

| 기호 Symbol |

도체Conductor | 절연체 두께기준값 Insulation Thickness (mm) |

시스 두께기준값 Insulation Thickness (mm) |

평균완성외경 Mean Overall Diameter |

최대도체저항 Max. Conductor Resistance at 20℃ |

절연저항 Insulation Resistance at |

||||||

| 공칭 단면적 Nominal Sectional Area (mm2) |

도체등급 Conductor Class |

최대 소선경 Maximum Diameter of Wire (mm) |

외경(약) Approx. Diameter (mm) |

하한값 Lower Limit (mm) |

상한값 Upper Limit (mm) |

동선 Copper (Ϊ/km) |

도금동선 Tin-coated copper (Ϊ/km) |

70℃ (㏁/km) |

90℃ (㏁/km) |

|||

| 연질비닐시스코드 60227 KS IEC 52 300/300V 70℃ |

2×0.5 | 5 | 0.21 | 0.9 | 0.5 | 0.6 | 4.6 | 5.9 | 39 | 40.1 | 0.012 | – |

| 2×0.75 | 0.21 | 1.1 | 0.5 | 0.6 | 4.9 | 6.3 | 26 | 26.7 | 0.01 | – | ||

| 3×0.5 | 5 | 0.21 | 0.9 | 0.5 | 0.6 | 4.9 | 6.3 | 39 | 40.1 | 0.012 | – | |

| 3×0.75 | 0.21 | 1.1 | 0.5 | 0.6 | 5.2 | 6.7 | 26 | 26.7 | 0.01 | – | ||

| 범용비닐시스코드 60227 KS IEC 53 300/500V 70℃ |

2×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.8 | 5.7 | 7.2 | 26 | 26.7 | 0.011 | – |

| 2×1.0 | 0.21 | 1.3 | 0.6 | 0.8 | 5.9 | 7.5 | 19.5 | 20 | 0.01 | – | ||

| 2×1.5 | 0.26 | 1.6 | 0.7 | 0.8 | 6.8 | 8.6 | 13.3 | 13.7 | 0.01 | – | ||

| 2×2.5 | 0.26 | 2.1 | 0.8 | 1 | 8.4 | 10.6 | 7.98 | 8.21 | 0.009 | – | ||

| 3×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.8 | 6 | 7.6 | 26 | 26.7 | 0.011 | – | |

| 3×1.0 | 0.21 | 1.3 | 0.6 | 0.8 | 6.3 | 8 | 19.5 | 20 | 0.01 | – | ||

| 3×1.5 | 0.26 | 1.6 | 0.7 | 0.9 | 7.4 | 9.4 | 13.3 | 13.7 | 0.01 | – | ||

| 3×2.5 | 0.26 | 2.1 | 0.8 | 1.1 | 9.2 | 11.4 | 7.98 | 8.21 | 0.009 | – | ||

| 4×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.8 | 6.6 | 8.3 | 26 | 26.7 | 0.011 | – | |

| 4×1.0 | 0.21 | 1.3 | 0.6 | 0.9 | 7.1 | 9 | 19.5 | 20 | 0.01 | – | ||

| 4×1.5 | 0.26 | 1.6 | 0.7 | 1 | 8.4 | 10.5 | 13.3 | 13.7 | 0.01 | – | ||

| 4×2.5 | 0.26 | 2.1 | 0.8 | 1.1 | 10.1 | 12.5 | 7.98 | 8.21 | 0.009 | – | ||

| 5×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.9 | 7.4 | 9.3 | 26 | 26.7 | 0.011 | – | |

| 5×1.0 | 0.21 | 1.3 | 0.6 | 0.9 | 7.8 | 9.8 | 19.5 | 20 | 0.01 | – | ||

| 5×1.5 | 0.26 | 1.6 | 0.7 | 1.1 | 9.3 | 11.6 | 13.3 | 13.7 | 0.01 | – | ||

| 5×2.5 | 0.26 | 2.1 | 0.8 | 1.2 | 11.2 | 13.9 | 7.98 | 8.21 | 0.009 | – | ||

| 내열성 연질비닐시스코드 60227 KS IEC 56 300/300V 90℃ |

2×0.5 | 5 | 0.21 | 0.9 | 0.5 | 0.6 | 4.6 | 5.9 | 39 | 40.1 | – | 0.012 |

| 2×0.75 | 0.21 | 1.1 | 0.5 | 0.6 | 4.9 | 6.3 | 26 | 26.7 | – | 0.01 | ||

| 3×0.5 | 5 | 0.21 | 0.9 | 0.5 | 0.6 | 4.9 | 6.3 | 39 | 40.1 | – | 0.012 | |

| 3×0.75 | 0.21 | 1.1 | 0.5 | 0.6 | 5.2 | 6.7 | 26 | 26.7 | – | 0.01 | ||

| 내열성 범용비닐시스코드 60227 KS IEC 57 300/500V 90℃ |

2×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.8 | 5.7 | 7.2 | 26 | 26.7 | – | 0.011 |

| 2×1.0 | 0.21 | 1.3 | 0.6 | 0.8 | 5.9 | 7.5 | 19.5 | 20 | – | 0.01 | ||

| 2×1.5 | 0.26 | 1.6 | 0.7 | 0.8 | 6.8 | 8.6 | 13.3 | 13.7 | – | 0.01 | ||

| 2×2.5 | 0.26 | 2.1 | 0.8 | 1 | 8.4 | 10.6 | 7.98 | 8.21 | – | 0.009 | ||

| 3×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.8 | 6 | 7.6 | 26 | 26.7 | – | 0.011 | |

| 3×1.0 | 0.21 | 1.3 | 0.6 | 0.8 | 6.3 | 8 | 19.5 | 20 | – | 0.01 | ||

| 3×1.5 | 0.26 | 1.6 | 0.7 | 0.9 | 7.4 | 9.4 | 13.3 | 13.7 | – | 0.01 | ||

| 3×2.5 | 0.26 | 2.1 | 0.8 | 1.1 | 9.2 | 11.4 | 7.98 | 8.21 | – | 0.009 | ||

| 4×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.8 | 6.6 | 8.3 | 26 | 26.7 | – | 0.011 | |

| 4×1.0 | 0.21 | 1.3 | 0.6 | 0.9 | 7.1 | 9 | 19.5 | 20 | – | 0.01 | ||

| 4×1.5 | 0.26 | 1.6 | 0.7 | 1 | 8.4 | 10.5 | 13.3 | 13.7 | – | 0.01 | ||

| 4×2.5 | 0.26 | 2.1 | 0.8 | 1.1 | 10.1 | 12.5 | 7.98 | 8.21 | – | 0.009 | ||

| 5×0.75 | 5 | 0.21 | 1.1 | 0.6 | 0.9 | 7.4 | 9.3 | 26 | 26.7 | – | 0.011 | |

| 5×1.0 | 0.21 | 1.3 | 0.6 | 0.9 | 7.8 | 9.8 | 19.5 | 20 | – | 0.01 | ||

| 5×1.5 | 0.26 | 1.6 | 0.7 | 1.1 | 9.3 | 11.6 | 13.3 | 13.7 | – | 0.01 | ||

| 5×2.5 | 0.26 | 2.1 | 0.8 | 1.2 | 11.2 | 13.9 | 7.98 | 8.21 | – | 0.009 | ||

DATA SHEET