![]()

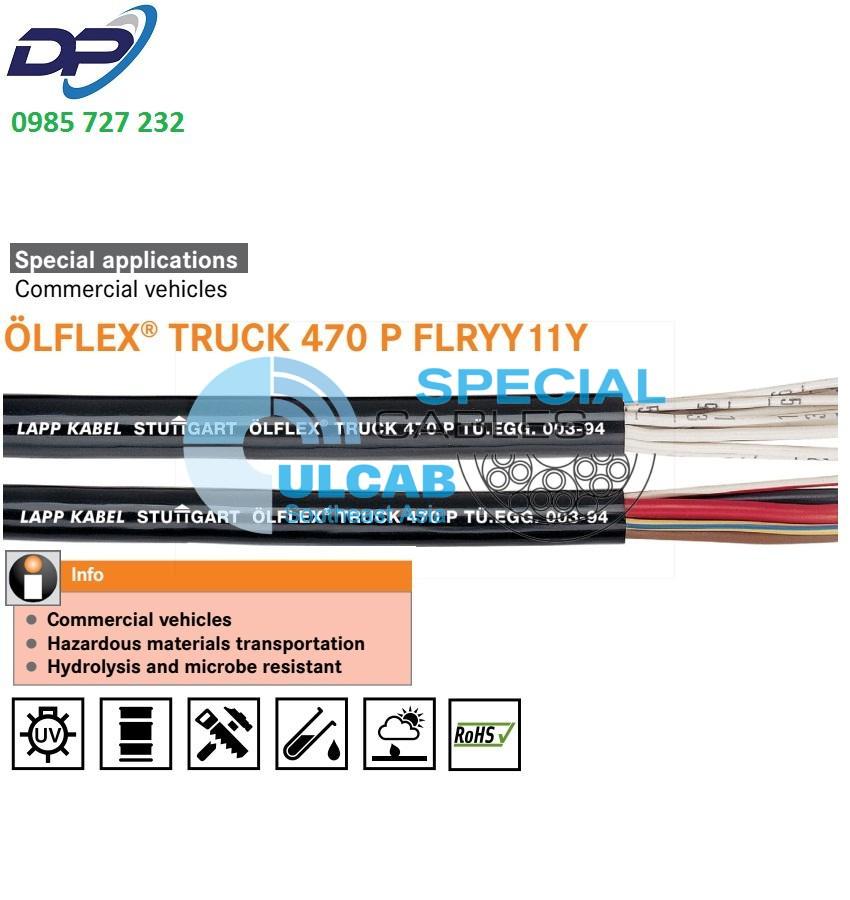

ÖLFLEX® TRUCK 470 P FLRYY11Y

ÖLFLEX® TRUCK 470 P FLRYY11Y, ADR/TÜV/DIN ISO 4141&6722, power and control cable for trucks/commercial vehicles, PUR sheath, resistant to UV/oil/cold/hydrolysis/microbes

- tested according to ECE-R 118.01

- Hazardous materials transportation

- Hydrolysis- and microbe-resistant

Benefits

- Special ADR approval

- ADR approval enables use in all trailers and semi-trailers transporting hazardous goods

Application range

- tested according to ECE-R 118.01

- Wiring electrical installations for all trailers and semi-trailers

Product features

- UV-resistant

- Resistant to cold temperatures

- Resistant to most oils, chemicals and weather conditions

- Resistant to hydrolysis and microbes

Norm references / approvals

- ISO 4141 and DIN/ISO 6722

Design

- Conductor made of bare copper wires

- PVC-based core insulation

- Special PVC-based inner sheath

- Outer sheath made of special polyurethane

Classification

- ETIM 5.0 Class-ID: EC000104

- ETIM 5.0 Class-Description: Control cable

Core identification code

- ISO 4141-3

Capacity of data pairs

- Related to length between cores, max. 50 pF/m and between each data transmission core and all other cores in the cable, max. 100 pF/m

Conductor design

- Fine wire according to DIN/ISO 6722

Minimum bending radius

- 12 x outer diameter

Nominal voltage

- 60 V

Test voltage

- 5 kV rms for at least 5 min.

Temperature range

- Fixed installation: -40°C to +85°C

- Area of application, class A

| Article number | Number of cores and mm² per conductor |

Outer diameter (mm) |

Colour | Copper index (kg/km) |

Weight (kg/km) |

| ÖLFLEX® TRUCK 470 P FLRYY11Y | |||||

| 7027080 | 2 x 1,0 | 6 | white-black | 19.2 | 55 |

| 7027081 | 2 x 1,0 | 6 | white-brown | 19.2 | 55 |

| 7027020 | 2 x 1,5 | 6.6 | white-black | 28.8 | 68 |

| 7027021 | 2 x 1,5 | 6.6 | white-brown | 28.8 | 68 |

| 7027082 | 3 x 1,0 | 6.3 | black-brown-blue | 28.80 | 67 |

| 7027022 | 3 x 1,0 | 6.3 | white/brown/blue, newest ISO design | 28.8 | 67 |

| 7027083 | 4 x 1,0 | 6.8 | white/black/red/brown | 38.4 | 81 |

| 7027038 | 4 x 1,5 | 7.5 | white/black/red/brown | 57.6 | 106 |

| 7027084 | 5 x 1,0 | 7.5 | white/brown/green/red/grey | 48 | 97 |

| 7027085 | 5 x 1,0 + 1 x 2,5 | 9 | 1.0 = green/brown/red/blue/violet; 2.5 = white | 72 | 133 |

| 7027086 | 5 x 1,0 + 1 x 2,5 | 9 | 1.0 = yellow/black/red/blue/violet; 2.5 = white | 72 | 133 |

| 7027025 | 5 x 1,0 + 1 x 2,5 | 9 | 1.0 = brown/green/red/grey/violet; 2.5 = white, newest ISO design | 72 | 133 |

| 7027087 | 6 x 1,5 + 1 x 2,5 | 10.3 | ISO 4141 1.5 = black/yellow/red/green/brown/blue; 2.5 = white | 110.4 | 187 |

| 7027130 | 7 x 0,75 | 7.3 | white/black/yellow/red/green/brown/blue | 50.4 | 101 |

| 7027088 | 7 x 1,5 | 8.9 | white/black/yellow/red/green/brown/blue | 100.8 | 166 |

| 7027089 | 8 x 1,5 + 1 x 2,5 | 11.7 | ISO 4141 + grey/violet | 139.2 | 239 |

| 7027090 | 10×1,5+3×2,5+1x(2×1,5) | 14.4 | white with black numbers; 1.5 = no. 1 – 3, 5 – 8, 10 – 12; 2.5 = no. 4, 9, 13; 1.5 = no. 14, 15 | 244.8 | 391 |

| 7027030 | 10×1,5+3×2,5+1x(2×1,5) | 14.4 | ISO 12098 | 244.8 | 395 |

| 7027091 | 10×1,5+3×2,5 | 14.4 | white with black numbers; 1.5 = no. 1 – 3, 5 – 8, 10 – 12; 2.5 = no. 4, 9, 13 | 216 | 367 |

| 7027031 | 10×1,5+3×2,5 | 14.4 | 1.5 = yellow/green/blue/black/brown/red/pink/grey/white-black/white-blue; 2.5 = white/orange/white-red |

216 | 367 |

| 7027046 | 2 x 0,75 + 2 x 1,5 | 7.2 | 0.75 = white-brown; 1.5 = yellow-green | 43.2 | 85 |

| 7027092 | 2 x 6 + 3 x 1,5 ABS | 12.1 | DIN 72570 6.0 = red/brown; 1.5 = black/yellow/white | 158.4 | 267 |

| 7027093 | 2×6+3×1,5+1x(2×1,5) EBS | 12.1 | DIN 72570 6.0 = red/brown; 1.5 = black/yellow/white; 1.5 = white-grey/white-brown | 187.2 | 321 |

| 7027094 | 2×4+3×1,5+1x(2×1,5) EBS | 11.9 | 4.0=red/brown; 1.5=black/yellow/white; 1.5=white-grey/white-brown | 148.8 | 257 |

| 7027024 | 18 x 1,5 | 13.7 | white with black numbers | 259.2 | 407 |

| 7027032 | 25 x 1,5 | 16.1 | white with black numbers | 360 | 560 |