![]()

Power and control cables

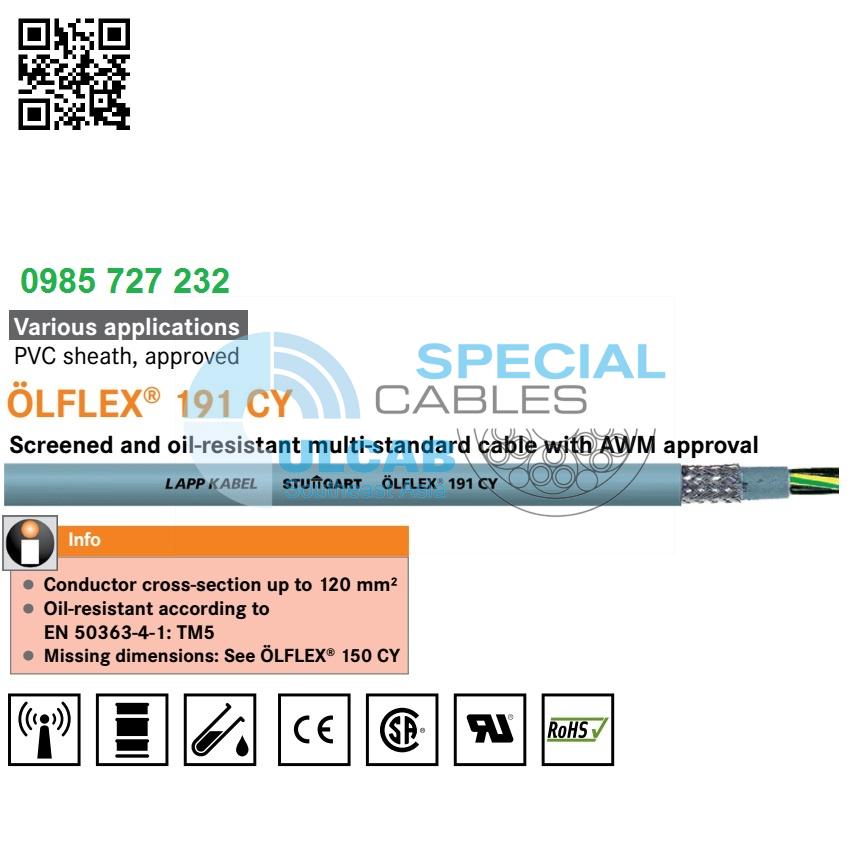

Various applications

PVC sheath, approved

LAPP KABEL ÖLFLEX® 191 CY

Screened and oil-resistant multi-standard cable with AWM approval

ÖLFLEX® 191 CY – PVC control cable with UL/CSA AWM, oil-resistant, shielded and flexible for various applications, UL/CSA: 600V, HAR: 300/500V

- Conductor cross-section up to 120 mm²

- Further dimensions with 0.75 mm²: see ÖLFLEX® 150 CY

- Oil-resistant according to EN 50363-4-1: TM5

Benefits

- High electrical safety due to 4 kV test voltage

- Versatile application possibilities

Application range

- Plant construction

Machine building

Heating and air-conditioning systems - In EMC-sensitive environments

(electromagnetic compatibility) - Mainly used in dry, damp and wet interiors (including water-oil mixtures), but not for outdoor use

- For fixed installation under medium mechanical loads and applications with occasional flexing with free, non-continuously recurring movement without tension load or compulsory guidance

- Note: For use of AWM (Appliance Wiring Material) cables in industrial machinery (USA) according to NFPA 79 ed. 2015: please see the catalogue appendix table T29

Product features

- Flame-retardant according to IEC 60332-1-2

and UL 1581 §1061 Cable Flame Test - Oil-resistant according to EN 50363-4-1: TM5

- High level of screening

Low coupling resistance

(max. 250 Ω/km at 30 MHz)

Norm references / approvals

- UL AWM Style 21098

CSA AWM I A/B II A/B - Multi-standard cables are designed in metric nominal cross sections in mm² or AWG/kcmil nominal sizes. The leading cross-section is specified in the table below, while the corresponding cross-section of the other system can be found in the appendix table T16 of this catalogue. For this corresponding secondary size, the conductor cross-section is generally larger.

Design

- Finely stranded bare copper wires

- PVC core insulation

- Cores twisted in layers

- PVC inner sheath, grey

- Tin-plated copper braiding

- PVC sheath, high oil-resistance, grey (RAL 7001)

■ Technical data

Classification

- ETIM 5.0 Class-ID: EC000104

- ETIM 5.0 Class-Description: Control cable

Core identification code

- Black with white numbers acc. to VDE 0293-1

Conductor design

- Fine wire according to VDE 0295,

class 5 / IEC 60228 class 5

Minimum bending radius

- Occasional flexing: 20 x outer diameter

- Fixed installation: 6 x outer diameter

Nominal voltage

- HAR U0/U: 300/500 V

- UL/CSA: 600 V

Test voltage

- 4000 V

Protective conductor

- G = with GN-YE protective conductor

- X = without protective conductor

Temperature range

- Occasional flexing: -5°C to +70°C

UL/CSA: -5°C to +90°C - Fixed installation: -40°C to +70°C

UL/CSA: -40°C to +90°C

| Article number |

Number of cores and mm² per conductor |

Outer diameter (mm) |

Copper index (kg/km) |

Weight (kg/km) |

| 0011234 | 7 G 0.75 | 10,5 | 85,9 | 187 |

| 0011202 | 2 X 1.0 | 8,4 | 48 | 126 |

| 0011180 | 3 G 1.0 | 8,8 | 55,8 | 122 |

| 0011181 | 4 G 1.0 | 9,6 | 80,8 | 157 |

| 0011182 | 5 G 1.0 | 10,3 | 89,4 | 183 |

| 0011183 | 7 G 1.0 | 11,2 | 99,9 | 207 |

| 0011184 | 12 G 1.0 | 14,6 | 175,7 | 342 |

| 0011185 | 18 G 1.0 | 17 | 241,7 | 472 |

| 0011186 | 25 G 1.0 | 20,1 | 341,7 | 648 |

| 0011302 | 2 X 1.5 | 9 | 64,7 | 156 |

| 0011187 | 3 G 1.5 | 9,6 | 89,1 | 166 |

| 0011188 | 4 G 1.5 | 10,3 | 96,6 | 191 |

| 0011189 | 5 G 1.5 | 11,3 | 111,2 | 222 |

| 0011190 | 7 G 1.5 | 12,1 | 145,2 | 270 |

| 0011191 | 12 G 1.5 | 16,1 | 257 | 464 |

| 0011192 | 18 G 1.5 | 18,7 | 382,8 | 679 |

| 0011193 | 25 G 1.5 | 23 | 546,2 | 952 |

| 0011194 | 3 G 2.5 | 10,8 | 111,1 | 221 |

| 0011195 | 4 G 2.5 | 11,4 | 140,6 | 269 |

| 0011196 | 5 G 2.5 | 12,9 | 167,3 | 325 |

| 0011197 | 7 G 2.5 | 14,1 | 240 | 421 |

| 30010542 | 12 G 2.5 | 17,9 | 414,9 | 769 |

| 30010543 | 18 G 2.5 | 22 | 626,1 | 1102 |

| 30010544 | 4 G 4 | 13,6 | 236,7 | 462 |

| 30010545 | 5 G 4 | 14,9 | 277,8 | 535 |

| 30010546 | 7 G 4 | 16,2 | 393,4 | 735 |

| 30010548 | 4 G 6 | 15,8 | 317,1 | 574 |

| 3023130 | 5 G 6 | 17,3 | 413,7 | 737 |

| 30010547 | 7 G 6 | 18,8 | 563,8 | 950 |

| 3023131 | 4 G 10 | 19,5 | 550,4 | 946 |

| 30010639 | 4 G 16 | 24,7 | 819,1 | 1189 |

| 3023132 | 4 G 25 | 28,5 | 1,165.0 | 1692 |

| 30010928 | 4 G 35 | 31,7 | 1,683.0 | 2700 |

| 3026535 | 4 G 50 | 39,7 | 2,342.0 | 3362 |

| 3025946 | 4 G 70 | 44,8 | 3,229.0 | 4490 |

| 3025947 | 4 G 95 | 50 | 4,010.0 | 5540 |

| 3026536 | 4 G 120 | 61,3 | 5,012.0 | 6960 |