![]()

Power and control cables

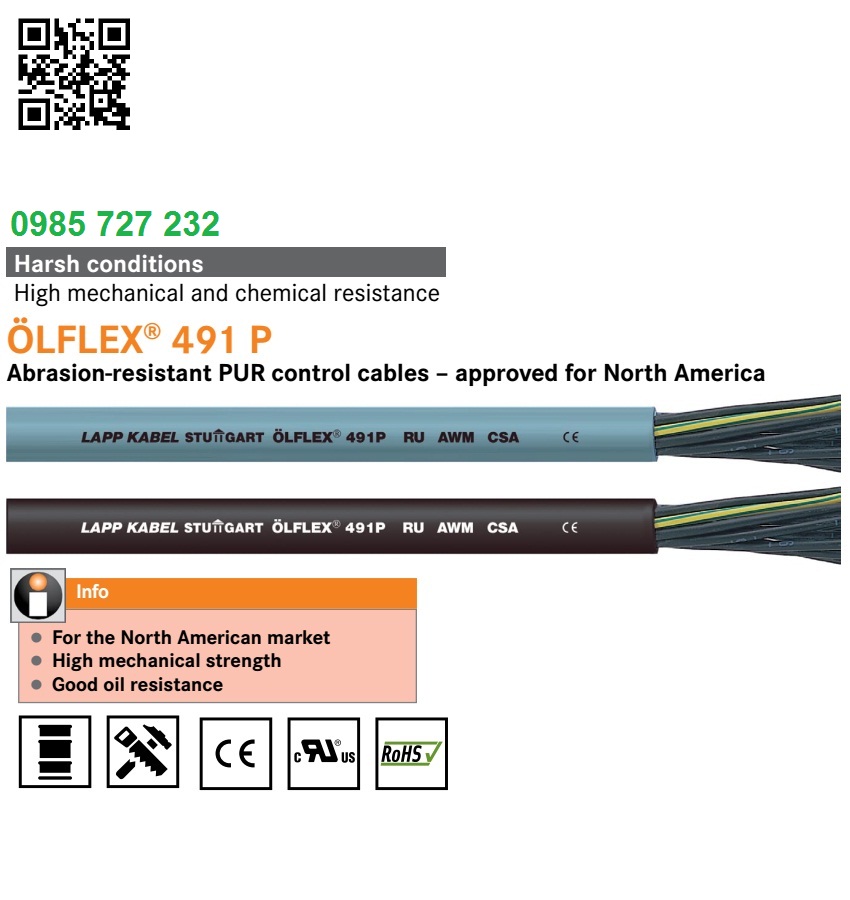

Harsh conditions

High mechanical and chemical resistance

LAPP KABEL ÖLFLEX® 491 P

Abrasion-resistant and oil-resistant PUR control cable for increased application requirements – certified for North America

ÖLFLEX® 491 P – PUR control cable with UL/CSA AWM certification for oil- and abrasion-resistant use in North America in apparatus construction, in industrial machines and machine tools.

- For the North American market

- High oil resistance

- Discontinued product –

Will be replaced by of ÖLFLEX® 409 P

Benefits

- Certified for the USA and Canada for export-oriented appliance and apparatus manufacturers

- Durable under harsh conditions thanks to robust PUR sheath material

- Resistant to contact with many mineral oil-based lubricants, diluted acids, aqueous alkaline solutions and other chemical media

- Metric flexible conductor design

- Also available as DESINA®-compliant power cable with black outer sheath colour

Application range

- Appliance and apparatus construction

- Plant construction

- Very suitable for oily wet areas within machine tools and transfer lines that are subject to normal mechanical stress

- Outdoor use is possible within the indicated temperature range

Product features

- High oil resistance

- Abrasion-resistant and notch-resistant

- Low-adhesive surface

- Flame-retardant according to IEC 60332-1-2 & CSA FT1

- Resistant to hydrolysis and microbes

Norm references / approvals

- In accordance with UL AWM style 20234

- cUL AWM II A/B FT1

- Multi-standard cables are designed in metric nominal cross sections in mm² or AWG/kcmil nominal sizes. The leading cross-section is specified in the table below, while the corresponding cross-section of the other system can be found in the appendix table T16 of this catalogue. For this corresponding secondary size, the conductor cross-section is generally larger.

Design

- Fine-wire, bare copper conductor

- Core insulation: Special PVC

- Cores twisted in layers

- Special polyurethane sheath (PUR)

- Sheath colour: Silver grey (RAL 7001)

- DESINA®-compliant: Black (RAL 9005)

■ Technical data

| Article number | Number of cores and mm² per conductor | Outer diameter (mm) | Copper index (kg/km) | Weight (kg/km) |

| ÖLFLEX® 491 P – sheath colour: black | ||||

| 0013009 | 3 G 1.0 | 7.7 | 27.0 | 73 |

| 0013017 | 3 G 1.5 | 8.3 | 44.0 | 100 |

| 0013018 | 4 G 1.5 | 9.0 | 58.0 | 123 |

| 0013019 | 5 G 1.5 | 9.8 | 72.0 | 150 |

| 0013020 | 7 G 1.5 | 10.7 | 101.0 | 197 |

| 0013021 | 12 G 1.5 | 13.8 | 173.4 | 344 |

| 0013023 | 25 G 1.5 | 20.0 | 360.0 | 682 |

| 0013024 | 3 G 2.5 | 9.2 | 72.0 | 152 |

| 0013025 | 4 G 2.5 | 9.9 | 96.0 | 200 |

| ÖLFLEX® 491 P – sheath colour: grey | ||||

| 0013208 | 2 X 1.0 | 7.3 | 19.2 | 62 |

| 0013210 | 4 G 1.0 | 8.2 | 35.0 | 89 |

| 0013212 | 7 G 1.0 | 9.7 | 61.0 | 138 |

| 0013213 | 12 G 1.0 | 12.5 | 105.0 | 232 |

| 0013214 | 18 G 1.0 | 14.8 | 157.0 | 340 |

| 0013215 | 25 G 1.0 | 17.8 | 218.0 | 454 |

| 0013223 | 3 G 1.5 | 8.3 | 44.0 | 100 |

| 0013220 | 4 G 1.5 | 9.0 | 57.6 | 123 |

| 0013222 | 7 G 1.5 | 10.7 | 101.0 | 197 |

| 0013225 | 12 G 1.5 | 13.8 | 173.0 | 344 |

| 0013226 | 18 G 1.5 | 16.6 | 260.0 | 488 |

| 0013227 | 25 G 1.5 | 20.0 | 360.0 | 682 |

■ Similar products

▯ ÖLFLEX® CLASSIC 400 P

■ Accessories

▯ Marking systems

▯ SKINTOP® Standard