Cáp Điều Khiển Helukabel MULTISPEED® 500-C-PUR | Chính Hãng – Chống Nhiễu – Cáp Chuyển Động – Giá Tốt Nhất

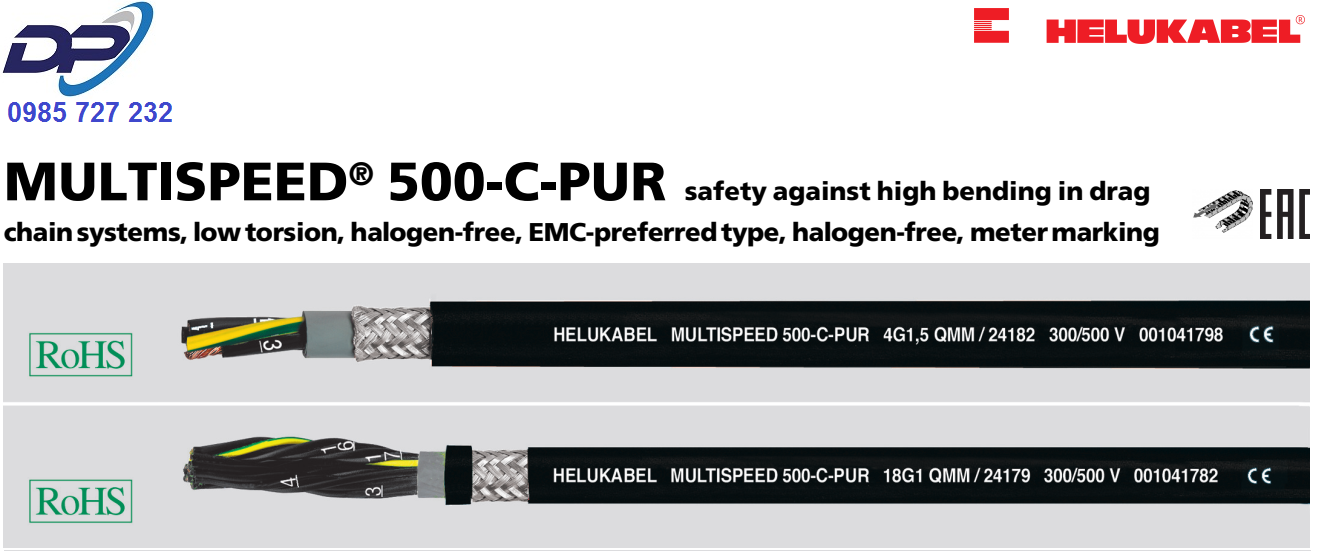

MULTISPEED® 500-C-PUR |

safety against high bending in drag chain systems, low torsion, halogen-free, meter marking, EMC-preferred type |

|

Technical data

- Special drag chain cables for high

mechanical stress adapted

to DIN VDE 0285-525-2-51 /

DIN EN 50525-2-51 and

DIN VDE 0285-525-2-21 /

DIN EN 50525-2-21 - Temperature range

flexing -30°C to +80°C

fixed installation -40°C to +80°C - Nominal voltage

U0/U 300/500 V - Test voltage

3000 V - Minimum bending radius

flexing 7,5x cable Ø

fixed installation 4x cable Ø - Coupling resistant

max. 250 Ohm/km - Radiation resistance

up to 100×106 cJ/kg (up to 100 Mrad)

Cable structure

- Bare copper conductor, fine wire,

Unilay with short lay length - Core insulation of special PP

- Core identification black cores with

continuous white numbering - GN-YE conductor, 3 cores and above

- Stranding:

< 7 cores: cores stranded in a layer with

optimal lay length around a filler as per

construction

≥ 7 cores: cores stranded with optimal

lay length to bunch-construction with

low torsion strength, optimal selected

short lay length around a filler - Special-TPE inner sheath, extruded as filler

with pressure, grey RAL 7001 - Tinned copper braided screen,

coverage 85% max., with optimal pitch

Fleece separator, ensure good dismantling

ability - Outer sheath of special PUR

- Sheath colour: black (RAL 9005)

- With meter marking

Properties

- Low adhesion

- High property of alternating bending strength

- High resistant to mechanical strain

- Long life durabilitys due to low

friction-resistance - High tensile strength, abrasion- and impact

resistance at low temperature - Tear resistance

- High stability and oil resistance

- Better chemical resistance

- Ozone- and UV-resistant

- Higher economical solution

- Reduced Ø, results low weight of moving

materials - The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers

Note

- G = with GN-YE conductor

x = without GN-YE conductor (OZ) - AWG sizes are approximate equivalent

values. The actual cross section is in mm². - Unscreened analogue type:

MULTISPEED® 500-PUR

Application

For permanent application in drag chains for long distances, high and low speed of movements. These cables are installed in dry, moist and wet rooms and in open air with free movement without tensile stress or forced movements. These robust and abrasion resistant special control cables are installed there, where the problems appear for the application in permanent stresses e. g. in energy drag chains. These cables are installed everywhere, where high requirements for the flexibility, abrasion, oxygen and chemical resistance are necessary. These screened cables are particularly suitable for the interference-free transmission in instrumentation and control engineering applications. For applications which go beyond standard solutions we recommend for our especially developed enquiry sheet for energy guiding systems.

EMC = Electromagnetic compatibility

To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

Data sheet

Certificate of compliance

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 24156 | 2 x 0,5 | 6,4 | 30,0 | 90,0 | 20 |

| 24157 | 3 G 0,5 | 6,7 | 36,0 | 104,0 | 20 |

| 24158 | 4 G 0,5 | 7,2 | 42,0 | 118,0 | 20 |

| 24159 | 5 G 0,5 | 7,6 | 48,0 | 148,0 | 20 |

| 24160 | 7 G 0,5 | 11,4 | 64,0 | 184,0 | 20 |

| 24161 | 9 G 0,5 | 11,4 | 80,0 | 219,0 | 20 |

| 24162 | 12 G 0,5 | 12,4 | 105,0 | 276,0 | 20 |

| 24163 | 18 G 0,5 | 14,7 | 137,0 | 378,0 | 20 |

| 24164 | 25 G 0,5 | 17,1 | 210,0 | 547,0 | 20 |

| 24165 | 2 x 0,75 | 6,8 | 40,0 | 100,0 | 19 |

| 24166 | 3 G 0,75 | 7,3 | 48,0 | 117,0 | 19 |

| 24167 | 4 G 0,75 | 7,8 | 55,0 | 143,0 | 19 |

| 24168 | 5 G 0,75 | 8,3 | 66,0 | 167,0 | 19 |

| 24169 | 7 G 0,75 | 12,7 | 85,0 | 229,0 | 19 |

| 24170 | 12 G 0,75 | 13,7 | 135,0 | 319,0 | 19 |

| 24171 | 18 G 0,75 | 17,1 | 190,0 | 492,0 | 19 |

| 24172 | 25 G 0,75 | 19,5 | 275,0 | 659,0 | 19 |

| 24173 | 2 x 1 | 7,1 | 50,0 | 120,0 | 18 |

| 24174 | 3 G 1 | 7,6 | 59,0 | 140,0 | 18 |

| 24175 | 4 G 1 | 8,1 | 70,0 | 167,0 | 18 |

| 24176 | 5 G 1 | 8,9 | 84,0 | 201,0 | 18 |

| 24177 | 7 G 1 | 13,6 | 106,0 | 256,0 | 18 |

| 24178 | 12 G 1 | 14,6 | 174,0 | 417,0 | 18 |

| 24179 | 18 G 1 | 18,4 | 240,0 | 557,0 | 18 |

| 24180 | 25 G 1 | 21,0 | 332,0 | 766,0 | 18 |

| 24181 | 3 G 1,5 | 8,4 | 75,0 | 170,0 | 16 |

| 24182 | 4 G 1,5 | 9,1 | 90,0 | 204,0 | 16 |

| 24183 | 5 G 1,5 | 10,2 | 108,0 | 236,0 | 16 |

| 24184 | 7 G 1,5 | 15,7 | 157,0 | 309,0 | 16 |

| 24185 | 12 G 1,5 | 17,4 | 240,0 | 509,0 | 16 |

| 24186 | 18 G 1,5 | 21,3 | 355,0 | 718,0 | 16 |

| 24187 | 25 G 1,5 | 24,3 | 448,0 | 944,0 | 16 |

| 24188 | 4 G 2,5 | 11,2 | 134,0 | 280,0 | 14 |

| 24189 | 5 G 2,5 | 12,2 | 175,0 | 346,0 | 14 |

| 24190 | 7 G 2,5 | 19,7 | 229,0 | 410,0 | 14 |