Cáp Điều Khiển Helukabel TOPFLEX® 600-C-PVC | Chính Hãng – Chống Nhiễu Lưới – Motor Cable – Giá Tốt Nhất

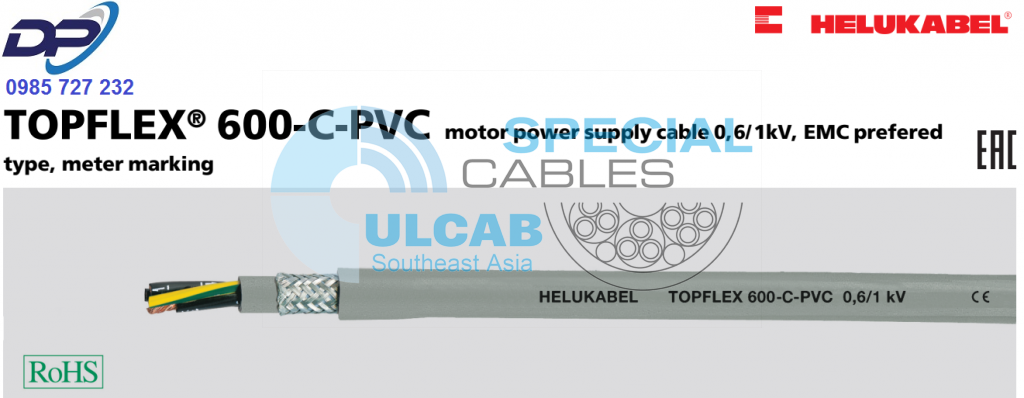

TOPFLEX® 600-C-PVC

motor power supply cable 0,6/1 kV, EMC-preferred type, meter marking

Technical data

- Special PVC-insulated sheathed cable

adapted to DIN VDE 0293, 0295 - Temperature range

flexing -15°C to +80°C

fixed installation -40°C to +80°C - Nominal voltage

U0/U 600/1000 V - Test voltage

4000 V - Breakdown voltage

min. 8000 V - Coupling resistance

max. 250 Ohm/km - Insulation resistance

min. 20 MOhm x km - Minimum bending radius

flexing 7.5x cable Ø

fixed installation 4x cable Ø - Radiation resistance

up to 80×106 cJ/kg (to 80 Mrad)

Cable structure

- Bare copper conductor, to

DIN VDE 0295 cl.5, fine wire,

IEC 60228 cl.5 - Core insulation of PVC

- Core identification to DIN VDE 0293

black cores with continuous white

numbering - GN-YE conductor

- Cores stranded in layers with

optimal lay length - Inner sheath of

- Tinned copper braided screen,

approx. 85% coverage - Outer sheath of special PVC

- Sheath colour: grey (RAL 7001)

- With meter marking

Properties

- Extensively oil resistant,

oil-/chemical resistance

see “Technical Informations” - The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers

Tests

- PVC self-extinguishing and flame retardant

acc. to DIN VDE 0482-332-1-2 /

DIN EN 60332-1-2 / IEC 60332-1-2

Note

- For use in drag chains, we

recommend our versions

TOPFLEX® 611-PUR and

TOPFLEX® 611-C-PUR - Unscreened analogue type:

TOPFLEX® 600-PVC

Application

As supply cable for electronically controlled servo-motors and connections to DNC motors. The cable is suitable for permanent and flexible installation for medium mechanical loads in dry, damp and wet environments.

EMC = Electromagnetic compatibility

To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

Data sheet

Certificate of compliance

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 22960 | 4 G 1,5 | 11,8 | 99,0 | 250,0 | 16 |

| 22961 | 4 G 2,5 | 13,8 | 169,0 | 360,0 | 14 |

| 22962 | 4 G 4 | 15,7 | 234,0 | 530,0 | 12 |

| 22963 | 4 G 6 | 17,3 | 316,0 | 620,0 | 10 |

| 22964 | 4 G 10 | 21,5 | 549,0 | 1050,0 | 8 |

| 22965 | 4 G 16 | 26,1 | 807,0 | 1465,0 | 6 |

| 22966 | 4 G 25 | 31,7 | 1169,0 | 1920,0 | 4 |

| 22967 | 4 G 35 | 34,5 | 1680,0 | 2515,0 | 2 |

| 22856 | 4 G 50 | 40,7 | 2370,0 | 3315,0 | 1 |

| 22857 | 4 G 70 | 46,0 | 3257,0 | 4600,0 | 2/0 |

| 22858 | 4 G 95 | 51,3 | 4060,0 | 6060,0 | 3/0 |

| 22859 | 4 G 120 | 56,4 | 5231,0 | 7315,0 | 4/0 |