Cáp Điện Helukabel TOPFLEX® 611-PUR | Chính Hãng – Cáp Chuyển Động – Motor Cable – Giá Tốt Nhất

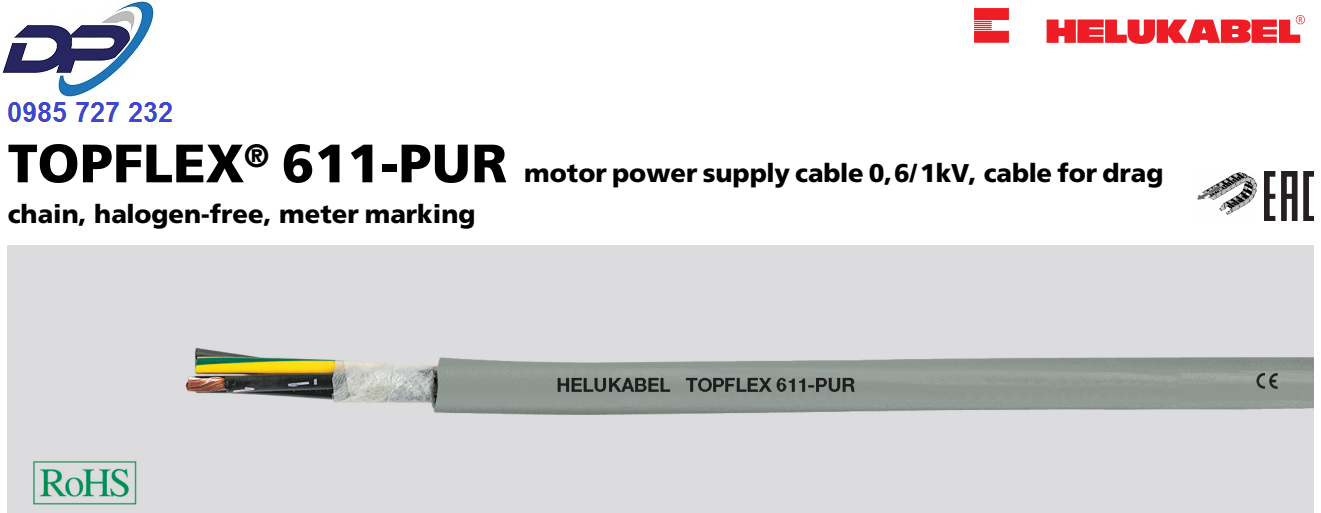

TOPFLEX® 611-PUR |

motor power supply cable 0,6/1 kV, cable for drag chain, halogen-free, meter marking |

|

Technical data

- Special-PUR drag chain cable

adapted to DIN VDE 0293, 0295, 0250,

DIN VDE 0285-525-1 / DIN EN 50525-1 - Temperature range

flexing -30°C to +80°C

fixed installation -40°C to +80°C - Nominal voltage

U0/U 600/1000 V - Test voltage

4000 V - Insulation resistance

min. 20 MOhm x km - Minimum bending radius

flexing 7,5x cable Ø

fixed installation 4x cable Ø

Cable structure

- Bare copper conductor, to

DIN VDE 0295 cl.6, extra fine wire,

BS 6360 cl.6, IEC 60228 cl.6 - Core insualtion of PP

- Core identification to DIN VDE 0293

black cores with continuous white

numbering - GN-YE conductor

- Cores stranded together with optimal

lay length and stabilising filler - Fleece wrapping facilitates sliding

- Outer sheath of PUR

- Sheath colour: grey (RAL 7001)

- With meter marking

Properties

- Adhesion-free, extremely abrasion

resistant, halogen-free, resistant to

hydrolysis and microbial attack - Resistant to UV-radiation,

oxygen and ozone - The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers

Note

- G = with GN-YE conductor

- For extreme applications extending beyond

standard solutions we recommend that

you request our questionnaire, which has

been especially designed for energy supply

systems. - Please observe applicable installation

regulations for use in energy supply chains. - Screened analogue type:

TOPFLEX® 611-C-PUR

Application

As optimized supply cable for the supply to motors, in particular to DNC motors, servo-motors. These cables are specially designed for use in power drag chains, handling equipment, robotics, tooling machinery, processing and manufacturing machinery. Optimised insulation materials ensure resistance to oils (including mineral oils), greases, coolants, hydraulic fluids as well as many alkalis and solvents. Favourable outer diameters, reduced weights and enhanced torsion characteristics assure the use in multi-layer operations with extremely high continuous bending loads. Suitable for outdoor use.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

Data sheet

Certificate of compliance

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 22870 | 4 G 1,5 | 8,0 | 58,0 | 125,0 | 16 |

| 22871 | 4 G 2,5 | 10,8 | 95,0 | 215,0 | 14 |

| 22872 | 4 G 4 | 12,5 | 154,0 | 310,0 | 12 |

| 22873 | 4 G 6 | 14,8 | 231,0 | 470,0 | 10 |

| 22874 | 4 G 10 | 18,8 | 384,0 | 760,0 | 8 |

| 22875 | 4 G 16 | 22,8 | 615,0 | 1250,0 | 6 |

| 22876 | 4 G 25 | 26,9 | 960,0 | 1510,0 | 4 |

| 22877 | 4 G 35 | 30,7 | 1344,0 | 2100,0 | 2 |

| 22978 | 4 G 50 | 36,5 | 1920,0 | 2950,0 | 1 |

| 22979 | 4 G 70 | 41,6 | 2640,0 | 4090,0 | 2/0 |

| 22980 | 4 G 95 | 48,2 | 3648,0 | 5580,0 | 3/0 |

| 22981 | 4 G 120 | 51,6 | 4608,0 | 7040,0 | 4/0 |