Cáp Điều Khiển Helukabel TOPFLEX®-PUR | Chính Hãng – Chống Nhiễu Lưới – Cáp Chuyển Động – Feedback Cables – Giá Tốt Nhất

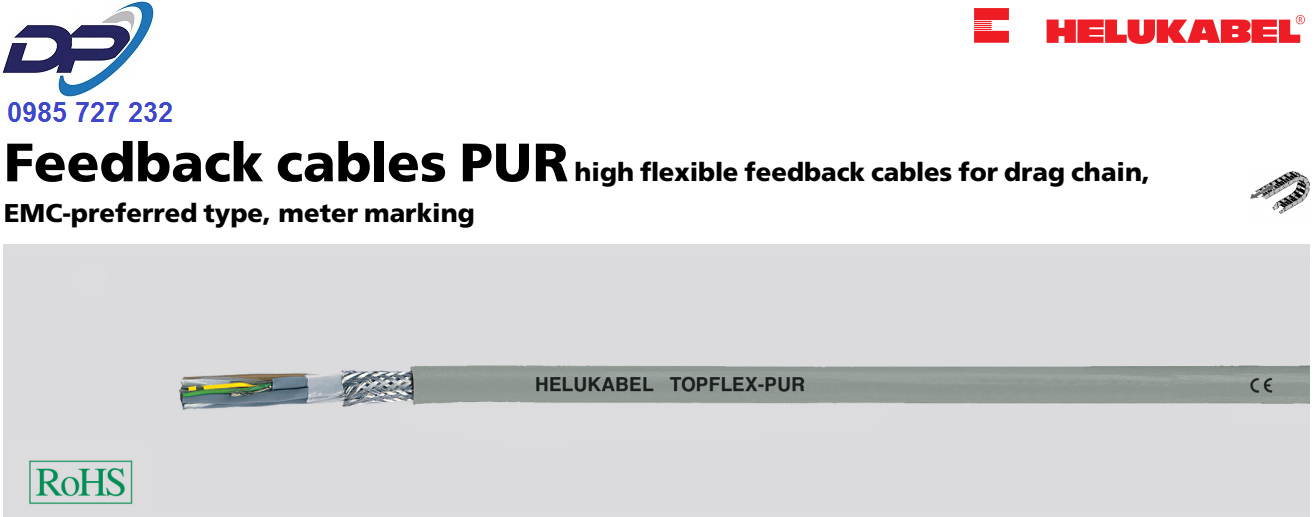

Feedback cables PUR |

high flexible feedback cables for drag chain, EMC-preferred type, meter marking |

|

Technical data

- Temperature range

flexing -30°C to +80°C

fixed installation -40°C to +80°C - Nominal voltage

TOPFLEX®-PUR 350 V

Tachofeedback-cable-C-PUR 450 V

Incremental Feedback-cable-C-PUR 250 V - Test voltage

core/core 2000 V

core/screen 1000 V - Insulation resistance

min. 20 MOhm x km - Minimum bending radius

flexing 10x cable Ø

fixed installation 5x cable Ø - Coupling resistance

max. 250 Ohm/km - Radiation resistance

up to 100×106 cJ/kg (up to 100 Mrad)

Cable structure

- Bare copper conductor, to

DIN VDE 0295 cl.6, extra fine wire,

BS 6360 cl.6, IEC 60228 cl.6 - Core insualtion of PP

- Part No. 22847 Cu-screen of single pairs

or single cores and PETP (polyethylene

terephthalate) sheath - Core identification see table below

- Single cores or pairs stranded

in layer with optimal lay length

(pairs part no. 22818) - Drain wire

- Tinned copper braided screen,

approx. 85% coverage - Outer sheath of special PUR, matt

- Sheath colour: see table below

Properties

- Special PUR outer sheath low adhesion

- Resistant to

Oils and fats

Acids and alkalis

Hydraulic fluids

Oxygen and ozone

UV-radiation

Hydrolysis

Microbial attack

Water and weathering effects - The high abrasion resistance and notch

resistance meet the highest requirements - The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers

Note

- For extreme applications extending beyond

standard solutions we recommend that

you request our questionnaire, which has

been especially designed for energy supply

systems. - Please observe the assembly instruction

for use in energy supply chains. - AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

Both cables fulfil different tasks for the control of servo-motors. The tachofeedback-cable or response cable serves the regulation of the motor speed and measurement of the actual values. The incremental feedback-cable or position response cable transfers the control signals for positioning and engineering characteristics and is used as the flexible connecting cable for tachometer, brakes and pulse transmitter in case of high mechanical stress in plant, machine and control engineering in dry, moist and wet rooms. Particularly suitable for continuous operating in drag chains, industrial robotics and handling equipment as these cables enable an excellent transmission of data and signals. Additional cores for the power supply to individual components are available. The braided screen guarantees reliable signal transmission. Optimum functionality, long service life and an excellent cost-performance ratio are given for the mentioned applications by the special compounds used for insulation and sheath.

EMC = Electromagnetic compatibility

To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

TOPFLEX®-PUR

| Part no. |

No.cores x cross-sec. mm² |

Core marking 0,14 mm² |

Core marking 0,5 mm² |

Sheath colour |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|---|---|---|

| 22847 | (3 x (2 x 0,14) + (2 x 0,5)) | DIN 47100 | white, brown | Grey | 8,3 | 78,0 | 103,0 | 26 |

| 22852 | 4 x 2 x 0,14 + 4 x 0,5 | brown+green, yellow+violet, grey+pink, red+blue | white, brown, white/green, brown/green | Grey | 8,4 | 73,0 | 105,0 | 26 |

| 22849 | (10 x 0,14 + 2 x 0,5) | DIN 47100 | white, brown | Grey | 7,2 | 39,0 | 83,0 | 26 |