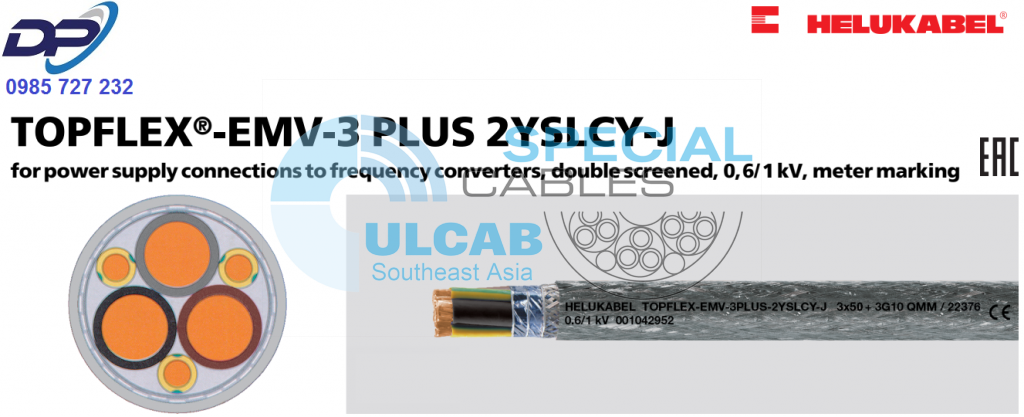

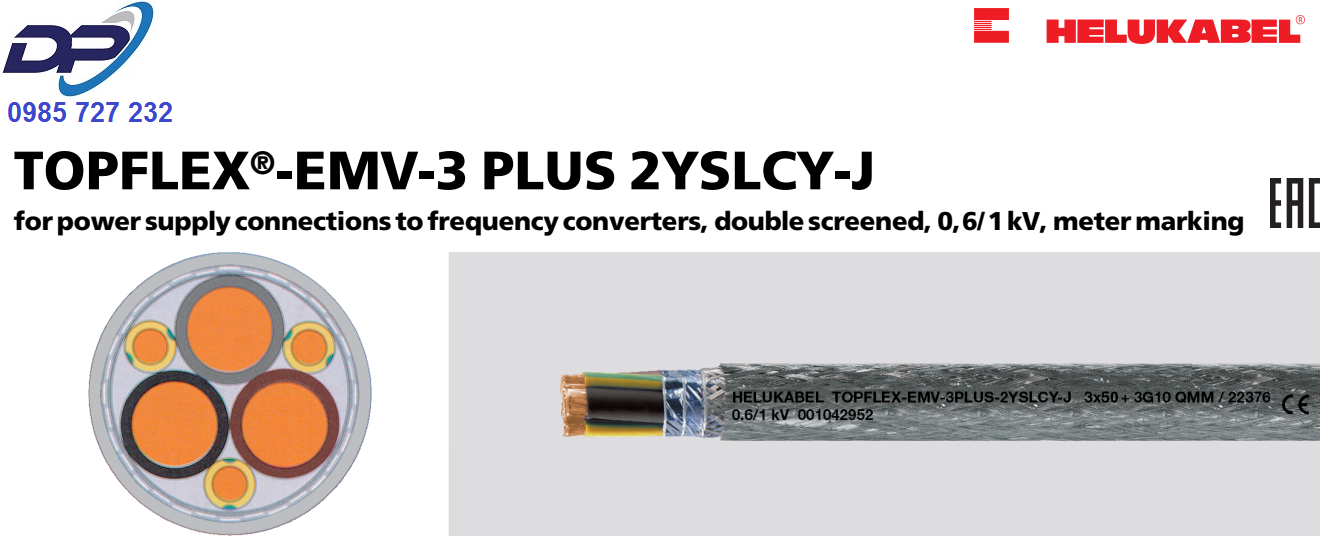

Cáp Điều Khiển Helukabel TOPFLEX®-EMV-3 PLUS 2YSLCY-J | Chính Hãng – Chống Nhiễu Lưới – Motor Cable – Giá Tốt Nhất

TOPFLEX®-EMV-3 PLUS 2YSLCY-J |

for power supply connections to frequency converters, 0.6/1 kV,

|

|

Technical data

- Special motor power supply cable for

frequency converters adapted to

DIN VDE 0250 - Temperature range

flexing +5°C to +70°C

fixed installation -40°C to +70°C - Nominal voltage

U0/U 600/1000 V - Max. permissible operating voltage

– 3-Phase and single phase

operation 700/1200 V

– DC operation 900/1800 V - Test voltage

4000 V - Coupling resistance

acc. to different cross sections

max. 250 Ohm/km - Minimum bending radius

flexing for cable Ø:

up to 12 mm: 10x cable Ø

> 12 mm: 15x cable Ø

fixed installation 4x cable Ø - Radiation resistance

up to 80×106 cJ/kg (up to 80 Mrad)

Cable structure

- Bare copper conductor, to

DIN VDE 0295 cl.5, fine wire,

BS 6360 cl.5, IEC 60228 cl.5 - Core insulation of polyethylene (PE)

- Core identification BK, BN, GY

- GN-YE conductor (divided into 3)

- 3+3-core structure

- Cores stranded in concentric layers

- 1. Screen with special aluminium film

2. Tinned copper braided screen,

approx. 85% coverage - Outer sheath of special PVC

- Sheath colour: transparent

- With meter marking

Properties

- Low mutual capacitance

- Low coupling resistance for high

electromagnetic compatibility - The minimum cross section of 0,75 mm²

meets the requirements of DIN EN 60204-1 - The 3 PLUS-construction of motor power

supply cables features a symmetrical

3-core design, improved in terms of EMC

characteristics comparing favorably with a

4-core version. The protective conductor

PE, divided into 3 is uniformly stranded in

the interstices. This enables an extremely

concentric structure. - This screened motor supply cable with

low mutual capacitance of the single cores

because of the special PE core insulation

and low screen capacitance enable a low-loss

transmission of the power compared to

PVC-sheathed connecting cables - Due to the optimal screening an

interference-free operation of

frequency converters is obtained - The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers

Tests

- PVC self-extinguishing and flame retardant

acc. to DIN VDE 0482-332-1-2,

DIN EN 60332-1-2, IEC 60332-1-2

(equivalent DIN VDE 0472 part 804

test method B) - Meets EMC requirements acc. to

EN 55011 and DIN VDE 0875 part 11

Note

- **) The current carrying capacity for

permanent operation at ambient temperature

of 30°C. For deviating ambient temperatures

the conversion factors should be used and

for further see the indication in

DIN VDE 0298-4. - AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

As a supply and connecting cable for medium mechanical stresses in fixed installations and forced movements in dry, moist and wet environments, not however for outdoor applications. Used in the automotive and food industries, environmental technology, packaging industry, chemical industry.

EMC = Electromagnetic compatibility

To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

Data sheet

Certificate of compliance

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Coupling resistance | Power ratings **)

with 3 loaded cores in Amperes |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. | |

|---|---|---|---|---|---|---|---|---|

| at 1 MHz

Ohm/km |

at 30 MHz

Ohm/km |

|||||||

| 22368 | 3 x 1,5 + 3 G 0,25 | 9,2 | 18 | 86,0 | 140,0 | 16 | ||

| 22369 | 3 x 2,5 + 3 G 0,5 | 10,8 | 18 | 210 | 26 | 144,0 | 220,0 | 14 |

| 22370 | 3 x 4 + 3 G 0,75 | 12,3 | 11 | 210 | 34 | 224,0 | 323,0 | 12 |

| 22371 | 3 x 6 + 3 G 1,0 | 14,0 | 6 | 150 | 44 | 298,0 | 420,0 | 10 |

| 22372 | 3 x 10 + 3 G 1,5 | 17,6 | 7 | 180 | 61 | 491,0 | 615,0 | 8 |

| 22373 | 3 x 16 + 3 G 2,5 | 21,2 | 9 | 190 | 82 | 723,0 | 819,0 | 6 |

| 22374 | 3 x 25 + 3 G 4,0 | 24,5 | 4 | 95 | 108 | 1138,0 | 1325,0 | 4 |

| 22375 | 3 x 35 + 3 G 6,0 | 26,9 | 3 | 85 | 135 | 1535,0 | 1718,0 | 2 |

| 22376 | 3 x 50 + 3 G 10,0 | 32,5 | 2 | 40 | 168 | 2208,0 | 2399,0 | 1 |

| 22377 | 3 x 70 + 3 G 10,0 | 35,5 | 2 | 45 | 207 | 2871,0 | 3056,0 | 2/0 |

| 22378 | 3 x 95 + 3 G 16,0 | 40,1 | 1 | 50 | 250 | 3953,0 | 4162,0 | 3/0 |

| 22379 | 3 x 120 + 3 G 16,0 | 44,4 | 292 | 4836,0 | 5074,0 | 4/0 | ||

| 22380 | 3 x 150 + 3 G 25,0 | 49,3 | 335 | 5412,0 | 6128,0 | 300 kcmil | ||

| 22381 | 3 x 185 + 3 G 35,0 | 55,1 | 382 | 6969,0 | 7189,0 | 350 kcmil | ||

| 22382 | 3 x 240 + 3 G 42,5 | 60,0 | 453 | 8540,0 | 9540,0 | 500 kcmil | ||