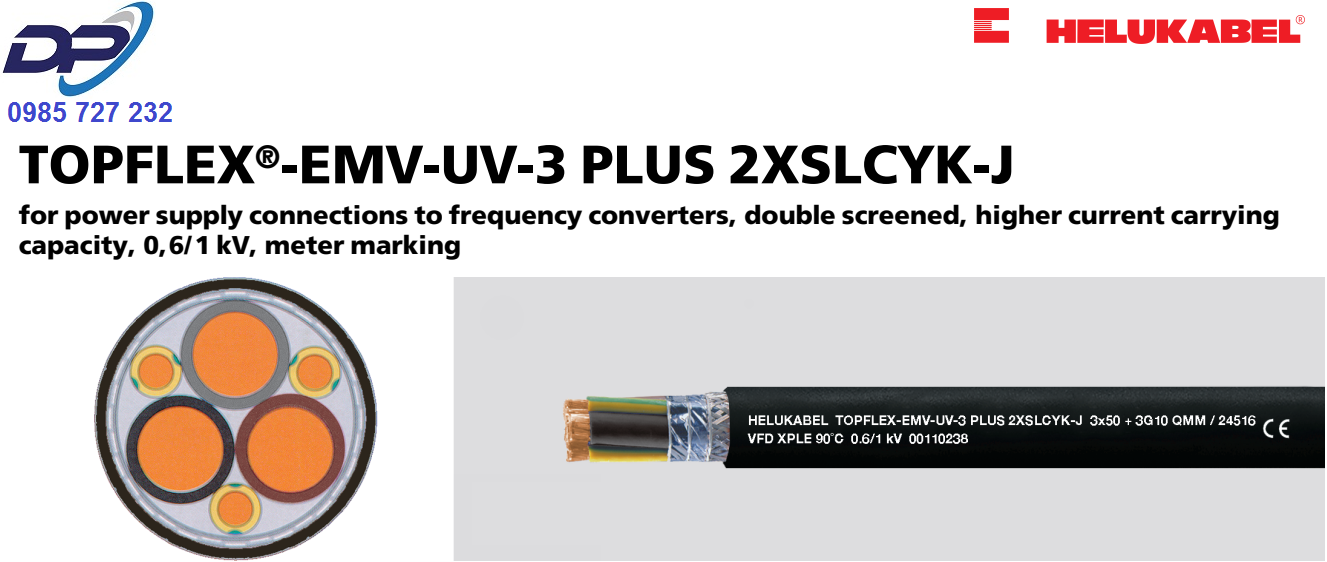

Cáp Điều Khiển Helukabel TOPFLEX®-EMV-UV-3 PLUS 2XSLCYK-J | Chính Hãng – Chống Nhiễu – Giá Tốt Nhất

TOPFLEX®-EMV-UV-3 PLUS 2XSLCYK-J |

for power supply connections to frequency converters, higher current carrying capacity, 0,6/1 kV,

|

Technical data

- Special motor power supply cable for

frequency converters adapted to

DIN VDE 0250 - Temperature range

flexing -5°C to +90°C

fixed installation -40°C to +90°C - Permissible operating temperature

at conductor +90°C - Nominal voltage

U0/U 600/1000 V - Max. permissible operating voltage

– 3-Phase and single phase

operation 700/1200 V

– DC operation 900/1800 V - Test voltage

4000 V - Coupling resistance

acc. to different cross sections

max. 250 Ohm/km - Minimum bending radius

flexing for cable Ø:

up to 12 mm: 10x cable Ø

> 12 mm: 15x cable Ø

fixed installation 4x cable Ø - Radiation resistance

up to 80×106 cJ/kg (up to 80 Mrad)

Cable structure

- Bare copper conductor, to

DIN VDE 0295 cl.5, fine wire,

BS 6360 cl.5, IEC 60228 cl.5 - Core insulation of cross-linked

polyethylene (XLPE) - Core identification BK, BN, GY

- GN-YE conductor (divided into 3)

- 3+3 core design

- Cores stranded in concentric layers

- 1. Screen with special aluminium film

2. Tinned copper braided screen,

approx. 85% coverage - Outer sheath of special PVC

- Sheath colour: black (RAL 9005)

- With meter marking

Properties

- Low mutual capacitance

- Low coupling resistance for high

electromagnetic compatibility - Due to the optimal screening an

interference-free operation of

frequency converters is obtained - The 3 PLUS-construction of motor power

supply cables features a symmetrical

3-core design, improved in terms of EMC

characteristics comparing favorably with a

4-core version. The protective conductor

PE, divided into 3 is uniformly stranded in

the interstices. This enables an extremely

concentric structure. - The minimum cross section of 0,75 mm²

meets the requirements of DIN EN 60204-1 - UV-resistant

- Outdoor application

- This screened motor supply cable with

low mutual capacitance of the single cores

because of the special XLPE core insulation

and low screen capacitance enable a low-loss

transmission of the power compared to

PVC-sheathed connecting cables - The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers

Tests

- self-extinguishing and flame retardant

acc. to DIN VDE 0482-332-1-2,

DIN EN 60332-1-2, IEC 60332-1-2

(equivalent DIN VDE 0472 part 804

test method B) - Meets EMC requirements acc. to

EN 55011 and DIN VDE 0875 part 11

Note

- **) The current carrying capacity for

permanent operation at ambient temperature

of 30°C. For deviating ambient temperatures

the conversion factors should be used and

for further see the indication in

DIN VDE 0298-4. - AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

As a supply and connecting cable for medium mechanical stresses in fixed installations and forced movements in dry, moist and wet environments and for outdoor applications, possible for installation in underground at 3×16+3G2,5 mm². Respecting the permissible operating temperature at the conductor of +90°C permits a higher current carrying capacity than PE insulated power distribution cables.Used in the automotive and food industries, environmental technology, packaging industry, chemical industry.

EMC = Electromagnetic compatibility

To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

Data sheet

Certificate of compliance

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Coupling resistance | Power ratings **)

with 3 loaded cores in Amperes |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. | |

|---|---|---|---|---|---|---|---|---|

| at 1 MHz

Ohm/km |

at 30 MHz

Ohm/km |

|||||||

| 24508 | 3 x 1,5 + 3 G 0,25 | 9,2 | 23 | 86,0 | 140,0 | 16 | ||

| 24509 | 3 x 2,5 + 3 G 0,5 | 10,8 | 18 | 210 | 32 | 144,0 | 220,0 | 14 |

| 24510 | 3 x 4 + 3 G 0,75 | 12,3 | 11 | 210 | 42 | 224,0 | 323,0 | 12 |

| 24511 | 3 x 6 + 3 G 1,0 | 14,0 | 6 | 150 | 54 | 298,0 | 420,0 | 10 |

| 24512 | 3 x 10 + 3 G 1,5 | 17,6 | 7 | 180 | 75 | 491,0 | 615,0 | 8 |

| 24513 | 3 x 16 + 3 G 2,5 | 20,4 | 9 | 190 | 100 | 723,0 | 819,0 | 6 |

| 24514 | 3 x 25 + 3 G 4,0 | 23,2 | 4 | 95 | 127 | 1138,0 | 1325,0 | 4 |

| 24515 | 3 x 35 + 3 G 6,0 | 26,1 | 3 | 85 | 158 | 1535,0 | 1718,0 | 2 |

| 24516 | 3 x 50 + 3 G 10,0 | 30,8 | 2 | 40 | 192 | 2208,0 | 2399,0 | 2 |

| 24517 | 3 x 70 + 3 G 10,0 | 34,2 | 2 | 45 | 246 | 2871,0 | 3056,0 | 2/0 |

| 24518 | 3 x 95 + 3 G 16,0 | 37,8 | 1 | 50 | 298 | 3953,0 | 4162,0 | 3/0 |

| 24519 | 3 x 120 + 3 G 16,0 | 42,6 | 346 | 4836,0 | 5075,0 | 4/0 | ||

| 24520 | 3 x 150 + 3 G 25,0 | 47,5 | 399 | 5412,0 | 6128,0 | 300 kcmil | ||

| 24521 | 3 x 185 + 3 G 35,0 | 53,4 | 456 | 6969,0 | 7189,0 | 350 kcmil | ||

| 24587 | 3 x 240 + 3 G 42,5 | 58,7 | 538 | 8540,0 | 9540,0 | 350 kcmil | ||