Dây Cáp Điều Khiển Helukabel SiHF/GL-P | Chính Hãng – Chống Nhiễu – Chịu Nhiệt Độ Cao – Silicone Cable – Giá Tốt Nhất

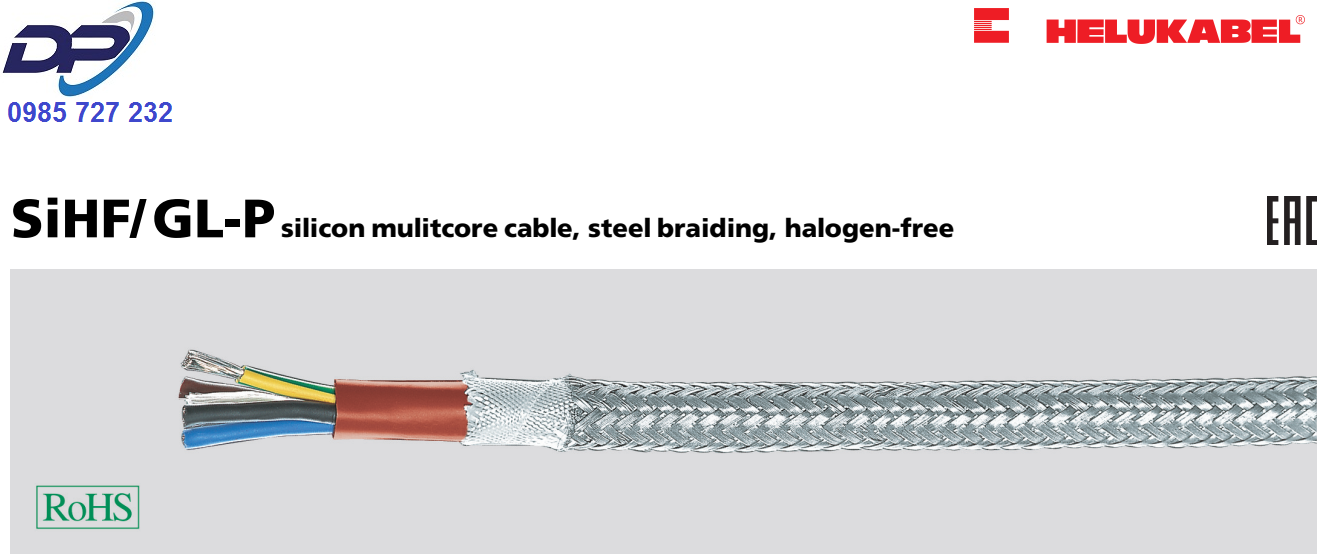

SiHF/GL-P |

Silicone mulitcore cable, steel braiding, halogen-free |

|

Technical data

- Special silicone multicore cable with higher

heat-resistance range adapted to

DIN VDE 0250-1 and

DIN VDE 0285-525-2-83 /

DIN EN 50525-2-83 - Temperature range

-60°C to +180°C

(for short time +220°C) - Temperature limit

at the conductor in operation +180°C - Nominal voltage U0/U 300/500 V

- Test voltage 2000 V

- Breakdown voltage min. 5000 V

- Insulation resistance

min. 200 MOhm x km - Power rating

at ambient temperature up to +145°C to

DIN VDE 0100 for higher temperatures valid:

150°C – load value 100%

155°C – load value 91%

160°C – load value 82%

165°C – load value 71%

170°C – load value 58%

175°C – load value 41% - Minimum bending radius

flexing 10x cable Ø

fixed installation 5x cable Ø - Radiation resistance

up to 20×106 cJ/kg (up to 20 Mrad)

Cable structure

- Tinned copper conductor, fine wire

acc. to DIN VDE 0295 cl.5 /

BS 6360 cl.5 / IEC 60228 cl.5 - Core insulation of silicone

- Core identification to DIN VDE 0293-308

– up to 5 cores coloured

– from 6 cores, black with continuous

white numbering - GN-YE conductor, 3 cores and above

- Cores stranded in layers with

optimal lay length - Sheath of silicone

- Glass fibre tape over the sheath

- Galvanized steel wire outer braiding

Properties

- Advantages

hardly changes of dielectric strength

and the insulation resistance also at

high temperatures, high ignition or

flash point, leave in case of fire an

insulating layer of SiO2 - For laying as a fixed installation only in

open or ventilated pipe systems as well

as in ducts. Otherwise the mechanical

properties of the silicone are reduced

by the enclosed air at temperatures

exceeding 90°C.

Tests

- Corrosiveness of combustion gases

acc. to DIN VDE 0482-267 /

DIN EN 50267-2-2 / IEC 60754-2 - Behaviour in fire

no flame propagation acc. to

DIN VDE 0482-332-1-2 /

DIN EN 60332-1-2 / IEC 60332-1-2

Note

- G = with GN-YE conductor

x = without GN-YE conductor - AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

Silicone cables screened with steel braiding were evolved for use wherever insulation is subjected to extreme temperature changes. They are heat-resistant for permanent temperature up to +180°C, for short time operation up to +220°C. The good performance of the environmental resistant properties means that silicone cables can be used at temperatures down to -60°C. Silicone cables are halogen-free cables and are especially suited for installation in power stations. They have also found their uses in the steel producing industries, aviation industry, ship building as well as in ceramic, glass and cement factories. The screened steel braiding ensures a disturbance-free transmission of signals and impulses.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 23062 | 2 x 0,75 | 7,9 | 14,4 | 90,0 | 19 |

| 23063 | 3 G 0,75 | 8,3 | 21,6 | 101,0 | 19 |

| 23064 | 4 G 0,75 | 9,3 | 29,0 | 129,0 | 19 |

| 23065 | 5 G 0,75 | 10,0 | 36,0 | 157,0 | 19 |

| 23067 | 7 G 0,75 | 10,7 | 50,0 | 177,0 | 19 |

| 23068 | 2 x 1 | 8,0 | 19,0 | 97,0 | 18 |

| 23069 | 3 G 1 | 8,9 | 29,0 | 122,0 | 18 |

| 23070 | 4 G 1 | 9,4 | 38,0 | 141,0 | 18 |

| 23071 | 5 G 1 | 10,4 | 48,0 | 166,0 | 18 |

| 23073 | 7 G 1 | 11,1 | 67,0 | 197,0 | 18 |

| 23074 | 2 x 1,5 | 9,0 | 29,0 | 127,0 | 16 |

| 23075 | 3 G 1,5 | 9,5 | 43,0 | 145,0 | 16 |

| 23076 | 4 G 1,5 | 10,3 | 58,0 | 173,0 | 16 |

| 23077 | 5 G 1,5 | 11,0 | 72,0 | 202,0 | 16 |

| 23078 | 6 G 1,5 | 12,0 | 86,0 | 240,0 | 16 |

| 23079 | 7 G 1,5 | 12,0 | 101,0 | 244,0 | 16 |

| 23080 | 8 G 1,5 | 13,0 | 115,0 | 261,0 | 16 |

| 23081 | 12 G 1,5 | 15,5 | 173,0 | 327,0 | 16 |

| 23082 | 14 G 1,5 | 16,2 | 202,0 | 382,0 | 16 |

| 23083 | 18 G 1,5 | 18,7 | 259,0 | 440,0 | 16 |

| 23084 | 24 G 1,5 | 21,5 | 346,0 | 600,0 | 16 |

| 23085 | 2 x 2,5 | 10,7 | 48,0 | 187,0 | 14 |

| 23086 | 3 G 2,5 | 11,2 | 72,0 | 205,0 | 14 |

| 23087 | 4 G 2,5 | 12,1 | 96,0 | 278,0 | 14 |

| 23088 | 5 G 2,5 | 13,3 | 120,0 | 322,0 | 14 |

| 23089 | 6 G 2,5 | 14,3 | 144,0 | 351,0 | 14 |

| 23090 | 7 G 2,5 | 14,4 | 168,0 | 380,0 | 14 |

| 23091 | 2 x 4 | 12,5 | 77,0 | 240,0 | 12 |

| 23092 | 3 G 4 | 13,0 | 115,0 | 311,0 | 12 |

| 23093 | 4 G 4 | 15,0 | 154,0 | 384,0 | 12 |

| 23094 | 5 G 4 | 16,0 | 192,0 | 454,0 | 12 |

| 23095 | 7 G 4 | 17,5 | 269,0 | 633,0 | 12 |

| 23096 | 2 x 6 | 15,1 | 115,0 | 321,0 | 10 |

| 23097 | 3 G 6 | 15,9 | 173,0 | 432,0 | 10 |

| 23098 | 4 G 6 | 18,0 | 230,0 | 544,0 | 10 |

| 23099 | 5 G 6 | 19,4 | 288,0 | 656,0 | 10 |

| 23100 | 7 G 6 | 20,7 | 403,0 | 768,0 | 10 |

| 23101 | 4 G 10 | 22,1 | 384,0 | 925,0 | 8 |

| 23102 | 4 G 16 | 26,1 | 614,0 | 1235,0 | 6 |

| 23103 | 4 G 25 | 30,4 | 960,0 | 1700,0 | 4 |