Dây Cáp Điều Khiển Helukabel MULTITHERM 400-ES | Chính Hãng – Chống Nhiễu – Chịu Nhiệt Độ Cao – Giá Tốt Nhất

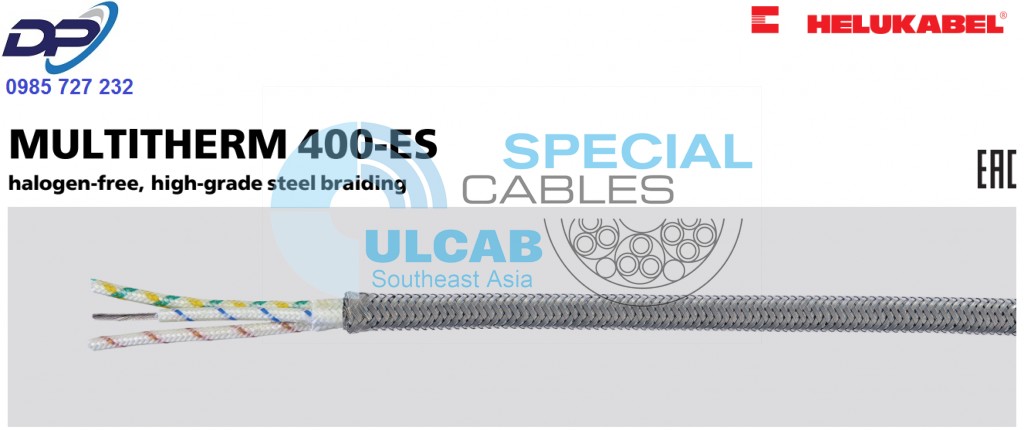

MULTITHERM 400-ES

halogen-free, high-grade steel braiding

Technical data

- Special core insulation

for high temperatures - Temperature range

-60°C to +400°C

(for short time +500°C) - Nominal voltage 500 V

- Test voltage 2500 V

- Minimum bending radius

5x cable Ø

Cable structure

- Copper-conductor nickel plated,

fine wire (ASTM B 355) - 1. Core insulation of braided glass-fibre

impregnated with silicone

2. Core insulation of braided glass-fibre

impregnated with silicone - Core identification

– No. of cores with GN-YE conductor

3 = GN-YE, BU, BN

4 = GN-YE, BK, BU, BN

5 = GN-YE, BK, BU, BN, WH

6 = GN-YE, BK, BU, BN, WH, RD

7 = GN-YE, BK, BU, BN, WH, RD, GY

– No. of cores without GN-YE conductor

2 = BU, BN

3 = BK, BU, BN

4 = BK, BU, BN, WH

5 = BK, BU, BN, WH, RD

6 = BK, BU, BN, WH, RD, GY

7 = BK, BU, BN, WH, RD, GY, GN - Overall lay up of cores

- Outer sheath of braided glass-fibre

impregnated with silicone - Braided high-grade steel,

coverage approx. 80%

Properties

- Asbestos and cadmium-free

Note

- Further sizes are available on request.

- AWG sizes are approximate equivalent

values. The actual cross section is in mm². - Unscreened analogue type:

MULTITHERM 400 - At temperatures above 200°C during the first commissioning, the impregnating varnish may degrade and leave only pure glass fibers remaining as insulation. This can be observed as evaporation.

Application

Where extremely high connecting and ambient temperatures occur, e. g. in iron and steel works, rolling mills, foundries, glass and ceramic plants, in power plant construction, in the chemical industry, nuclear technology, crude oil engineering, in technical applications in medicine, as well as for wiring resistances in electrical heating equipment, furnaces and machinery in thermoplastic forming. Due to the special construction of the cable, a maximum temperature of approx. 220°C is recommended for use in damp environments. Applications at temperatures above this should be used in dry environments only. The robust braiding of high-grade steel protects the cable from aggressive atmospheres and mechanical stresses. The braided screen can also be used for earthing purposes.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Max. permiss. current carrying capacity at +340°C (A) |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|---|

| 52018 | 2 x 0,5 | 7,1 | 10,0 | 3,3 | 84,0 | 20 |

| 52019 | 3 x 0,5 | 7,3 | 15,0 | 3,1 | 89,0 | 20 |

| 52020 | 4 x 0,5 | 8,4 | 19,0 | 3,0 | 111,0 | 20 |

| 52021 | 5 x 0,5 | 8,9 | 25,0 | 2,9 | 126,0 | 20 |

| 52022 | 6 x 0,5 | 9,5 | 30,0 | 2,8 | 146,0 | 20 |

| 52023 | 7 x 0,5 | 9,6 | 34,0 | 2,7 | 158,0 | 20 |

| 52024 | 2 x 0,75 | 7,6 | 14,4 | 5,1 | 95,0 | 19 |

| 52025 | 3 x 0,75 | 7,9 | 21,6 | 5,1 | 109,0 | 19 |

| 52026 | 4 x 0,75 | 8,9 | 29,0 | 4,9 | 131,0 | 19 |

| 52027 | 5 x 0,75 | 9,7 | 36,0 | 4,7 | 157,0 | 19 |

| 52028 | 6 x 0,75 | 10,4 | 43,0 | 4,5 | 177,0 | 19 |

| 52029 | 7 x 0,75 | 10,6 | 50,0 | 4,4 | 190,0 | 19 |

| 52030 | 2 x 1 | 7,8 | 19,0 | 7,0 | 105,0 | 18 |

| 52031 | 3 x 1 | 8,7 | 29,0 | 6,7 | 126,0 | 18 |

| 52032 | 4 x 1 | 9,2 | 38,0 | 6,4 | 148,0 | 18 |

| 52033 | 5 x 1 | 10,0 | 48,0 | 6,2 | 174,0 | 18 |

| 52034 | 6 x 1 | 10,7 | 58,0 | 6,0 | 198,0 | 18 |

| 52035 | 7 x 1 | 10,9 | 67,0 | 5,8 | 212,0 | 18 |

| 52036 | 2 x 1,5 | 8,9 | 29,0 | 9,4 | 132,0 | 16 |

| 52037 | 3 x 1,5 | 9,2 | 43,0 | 9,0 | 153,0 | 16 |

| 52038 | 4 x 1,5 | 10,0 | 58,0 | 8,6 | 183,0 | 16 |

| 52039 | 5 x 1,5 | 10,9 | 72,0 | 8,3 | 212,0 | 16 |

| 52040 | 6 x 1,5 | 11,6 | 88,0 | 8,0 | 241,0 | 16 |

| 52041 | 7 x 1,5 | 11,9 | 101,0 | 7,8 | 259,0 | 16 |

| 52042 | 2 x 2,5 | 10,1 | 48,0 | 12,2 | 191,0 | 14 |

| 52043 | 3 x 2,5 | 10,6 | 72,0 | 11,6 | 213,0 | 14 |

| 52044 | 4 x 2,5 | 11,5 | 96,0 | 11,2 | 256,0 | 14 |

| 52045 | 5 x 2,5 | 12,7 | 120,0 | 10,8 | 307,0 | 14 |

| 52046 | 6 x 2,5 | 14,9 | 144,0 | 10,4 | 359,0 | 14 |

| 52047 | 7 x 2,5 | 15,1 | 168,0 | 10,1 | 388,0 | 14 |

| 52048 | 2 x 4 | 11,9 | 77,0 | 16,0 | 260,0 | 12 |

| 52049 | 3 x 4 | 12,3 | 115,0 | 15,3 | 303,0 | 12 |

| 52050 | 4 x 4 | 15,1 | 154,0 | 14,6 | 378,0 | 12 |

| 52051 | 5 x 4 | 15,6 | 192,0 | 14,1 | 458,0 | 12 |

| 52052 | 7 x 4 | 16,6 | 270,0 | 13,3 | 593,0 | 12 |

| 52053 | 3 x 6 | 16,3 | 173,0 | 20,0 | 442,0 | 10 |

| 52054 | 4 x 6 | 18,3 | 230,0 | 19,0 | 567,0 | 10 |

| 52055 | 5 x 6 | 19,8 | 288,0 | 18,0 | 671,0 | 10 |

| 52056 | 4 x 10 | 22,1 | 384,0 | 26,0 | 866,0 | 8 |

| 52057 | 4 x 16 | 26,6 | 615,0 | 34,0 | 1203,0 | 6 |