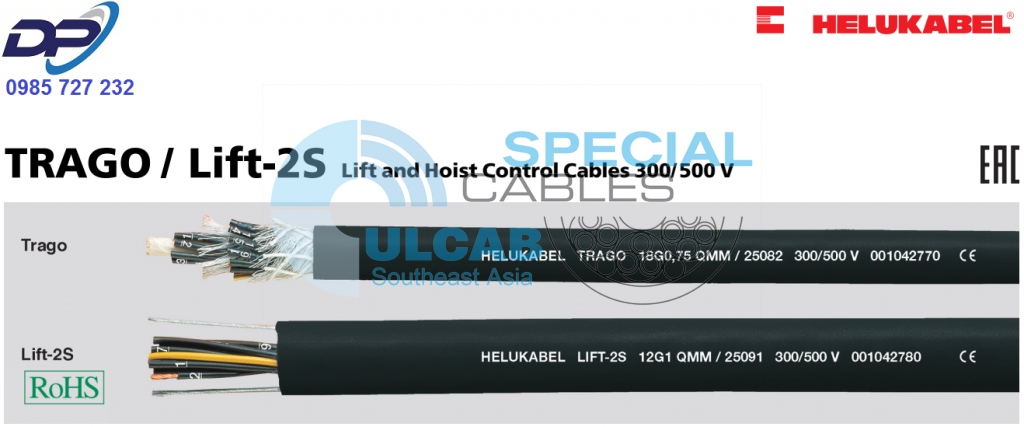

Dây Cáp Điều Khiển Helukabel Lift-2S | Chính Hãng – Giá Tốt Nhất

Lift-2S |

Lift and Hoist Control Cables 300/500 V |

|

Technical data

- Lift hoist control cables with strain bearing

element Special PVC-compound for core

and sheath, adapted to DIN VDE 0250 - Temperature range

flexing -15°C to +70°C

fixed installation -40°C to +70°C - Max. conductor temperature

under load +70°C

circuit conditions +150°C - Nominal voltage

U0/U 300/500 V - Test voltage

3000 V - Breakdown voltage

min. 6000 V - Minimum bending radius

20x cable Ø

Cable structure

- Bare copper conductor, to

DIN VDE 0295 cl.6, extra fine wire,

BS 6360 cl.6, IEC 60228 cl.6 - Core insualtion of special PVC, TI2 to

DIN VDE 0207-363-3 / DIN EN 50363-3 - Core identification to DIN VDE 0293

- GN-YE conductor

- Special hemp support braid

for Trago type with central

support core of hemp

for Lift-2S type with 2 outer

steel support wires - Cores stranded in layers with

optimal lay length - Multi-layer wrapping functioning as a

support braid - Outer sheath of special PVC TM2 to

DIN VDE 0207-363-4-1/DIN EN 50363-4-1 - Sheath colour: black (RAL 9005)

Properties

- The materials used during manufacturing

are cadmium-free, contain no silicone

and are free from substances harmful

to the wetting properties of lacquers - UV-resistant

Tests

- PVC self-extinguishing and flame retardant

acc. to DIN VDE 0482-332-1-2 /

DIN EN 60332-1-2 / IEC 60332-1-2

Note

- G = with GN-YE conductor

- AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

These cables are used as control or feeder cables in lifts and hoists. The special attention given to both production and material quality for these cables has made them ideal even for use under extreme conditions. HELUKABEL®-Lift-2S has also proven itself to be ideally suited for installation in conveyor systems and manual control units. The external steel support wires can be dismounted without damaging the cable insulation.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

Lift-2S with 2 external support cores

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

Support core | Pendal length max. m |

AWG-No. |

|---|---|---|---|---|---|---|---|

| 25091 | 12 G 1 | 13,5 | 115,2 | 446,0 | Steel | 50 | 18 |

| 25092 | 18 G 1 | 16,2 | 172,8 | 528,0 | Steel | 50 | 18 |

| 25093 | 25 G 1 | 19,0 | 240,0 | 660,0 | Steel | 50 | 18 |

| 25094 | 30 G 1 | 21,9 | 288,0 | 760,0 | Steel | 50 | 18 |

| 25095 | 8 G 1,5 | 14,7 | 115,0 | 425,0 | Steel | 50 | 16 |

| 25096 | 12 G 1,5 | 16,0 | 172,8 | 505,0 | Steel | 50 | 16 |

| 25097 | 15 G 1,5 | 19,5 | 230,0 | 575,0 | Steel | 50 | 16 |

| 25098 | 18 G 1,5 | 19,3 | 259,0 | 640,0 | Steel | 50 | 16 |

| 25099 | 20 G 1,5 | 19,5 | 288,0 | 715,0 | Steel | 50 | 16 |

| 25100 | 24 G 1,5 | 22,5 | 346,0 | 820,0 | Steel | 50 | 16 |

TRAGO with central support

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

Support core | Pendal length max. m |

AWG-No. |

|---|---|---|---|---|---|---|---|

| 25080 | 7 G 0,75 | 15,4 | 50,0 | 290,0 | Hemp | 250 | 19 |

| 25081 | 12 G 0,75 | 19,2 | 86,0 | 360,0 | Hemp | 220 | 19 |

| 25082 | 18 G 0,75 | 21,0 | 130,0 | 455,0 | Hemp | 110 | 19 |

| 25083 | 24 G 0,75 | 23,0 | 173,0 | 535,0 | Hemp | 90 | 19 |

| 25084 | 7 G 1 | 14,9 | 67,0 | 222,0 | Hemp | 80 | 18 |

| 25085 | 12 G 1 | 20,0 | 115,0 | 415,0 | Hemp | 80 | 18 |

| 25086 | 18 G 1 | 21,4 | 173,0 | 450,0 | Hemp | 70 | 18 |

| 25087 | 20 G 1 | 21,6 | 192,0 | 490,0 | Hemp | 70 | 18 |

| 25088 | 24 G 1 | 23,2 | 230,0 | 605,0 | Hemp | 60 | 18 |

| 25089 | 36 G 1 | 26,1 | 346,0 | 950,0 | Hemp | 90 | 18 |