Dây Cáp Điều Khiển Helukabel NSHTÖU | Chính Hãng – Giá Tốt Nhất

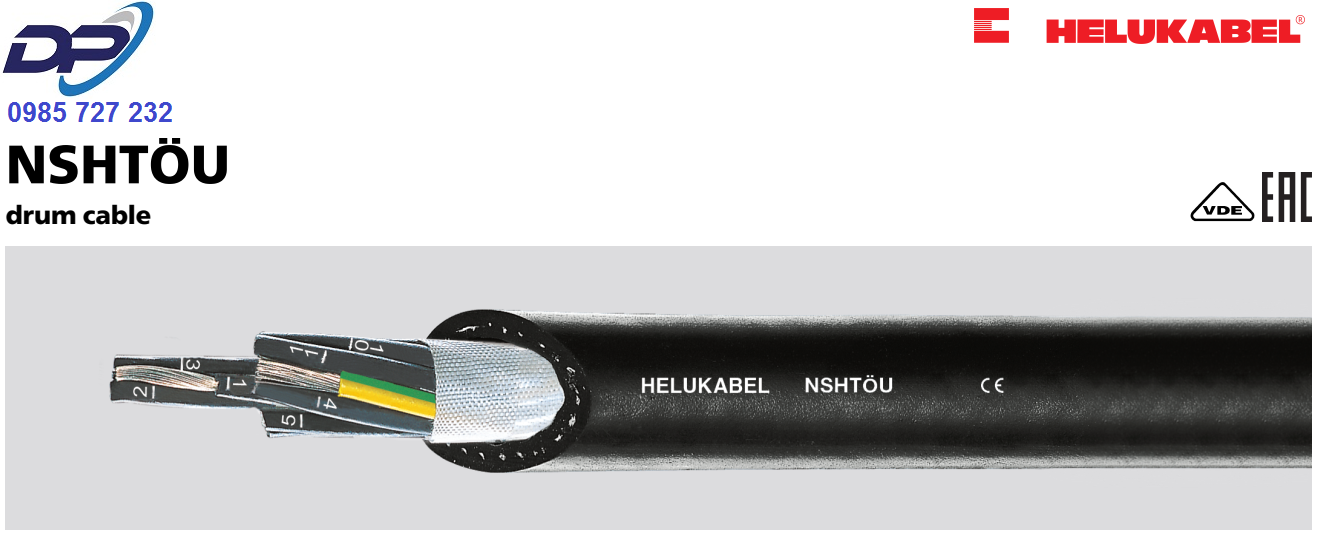

NSHTÖU

Drum cable

Technical data

- Special-drum cable acc. to

DIN VDE 0250-814 - Temperature range

flexing -25°C to +70°C

fixed installation -40°C to +70°C - Max. temperatur at the conductor

during operation +60°C

in case of short circuit +200°C - Nominal voltage

U0/U 0.6/1 kV - Max. permissible operating voltage

– 3-Phase and single phase

operation 700/1200 V

– DC operation 900/1800 V - Test voltage

2500 V - Minimum bending radius

7,5x cable Ø - Radiation resistance

up to 20×106 cJ/kg (up to 20 Mrad)

Cable structure

- Tinned copper conductor, to

DIN VDE 0295 cl.5, fine wire,

BS 6360 cl.5, IEC 60228 cl.5 - Core insulation of rubber

compound type GI1 to

DIN VDE 0207-20 - Core identification to DIN VDE 0293

– up to 5 cores coloured

– from 6 cores, black with continuous

white numbering - GN-YE conductor

- Cores stranded (without elongated central

core) with max. lay length of 8x Ø over the

stranding layers - Textile tape

- Inner sheath

- Torsion protection betweeen

inner and outer sheath - Outer sheath of rubber

compound type 5GM2 to

DIN VDE 0207-21 - Sheath colour: black

Properties

- Designed and developed for

horizontal drum-operation - Resistant to ozone,

oils, acids, fats, gazoline,

solvents and chemicals

Tests

- Behaviour in fire acc. to

DIN VDE 0482-332-1-2 /

DIN EN 60332-2-1 / IEC 60332-1-2 - Oil resistant acc. to

DIN VDE 0473-811-404/DIN EN 60811-404

Note

- G = with GN-YE conductor

- Permissible running speed up to

max. 120 m/min - During the installation and operation

the tensile stress on conductor may

not increase 15 N/mm² - Accelaration not more than 0,4 m/s²

- In case of high mechanical stress,

especially of high dynamic tensile

stress result high accelaration, the

permissible stress must be defined

in each case - AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

Trailing cables are used for high mechanical stress, especially for applications with frequent winding and unwinding with simultaneous tensile and torsional stress, for building machinery, conveyors, shifts and cranes. They are used as robust and all weather resistant cables of roughest operations in mining and in flexible handling equipment and railway motors. The cables are suitable for outdoor installation in dry, damp and wet places as well in open air. For applications which go beyond standard solutions we recommend that you fill out our especially developed questionnaire for reeling cables. Please read the installation instructions, see chapter “Technical Informations”.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

app. mm |

Cop. weight kg / km |

Weight

app. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 26001 | 3 G 1,5 | 13,6 | 47,0 | 236,0 | 16 |

| 26029 | 4 G 1,5 | 14,0 | 58,0 | 274,0 | 16 |

| 26002 | 5 G 1,5 | 14,5 | 81,0 | 316,0 | 16 |

| 26003 | 7 G 1,5 | 18,8 | 115,0 | 440,0 | 16 |

| 26004 | 12 G 1,5 | 21,0 | 196,0 | 606,0 | 16 |

| 26005 | 16 G 1,5 | 24,5 | 259,0 | 696,0 | 16 |

| 26006 | 18 G 1,5 | 25,5 | 271,0 | 750,0 | 16 |

| 26007 | 24 G 1,5 | 27,5 | 390,0 | 1150,0 | 16 |

| 26008 | 30 G 1,5 | 29,5 | 432,0 | 1325,0 | 16 |

| 26009 | 3 G 2,5 | 15,3 | 74,0 | 305,0 | 14 |

| 26010 | 4 G 2,5 | 16,5 | 98,0 | 350,0 | 14 |

| 26011 | 5 G 2,5 | 17,5 | 124,0 | 465,0 | 14 |

| 26012 | 7 G 2,5 | 20,0 | 168,0 | 576,0 | 14 |

| 26013 | 12 G 2,5 | 23,5 | 308,0 | 850,0 | 14 |

| 26014 | 18 G 2,5 | 28,0 | 451,0 | 1181,0 | 14 |

| 26015 | 24 G 2,5 | 32,5 | 615,0 | 1550,0 | 14 |

| 26016 | 30 G 2,5 | 34,0 | 770,0 | 1810,0 | 14 |

| 26017 | 40 G 2,5 | 42,5 | 1080,0 | 3110,0 | 14 |

| 26018 | 50 G 2,5 | 46,5 | 1200,0 | 3200,0 | 14 |

| 26019 | 4 G 4 | 18,5 | 158,0 | 510,0 | 12 |

| 26030 | 5 G 4 | 21,5 | 220,0 | 635,0 | 12 |

| 26020 | 4 G 6 | 21,0 | 241,0 | 650,0 | 10 |

| 26031 | 5 G 6 | 23,5 | 317,0 | 800,0 | 10 |

| 26021 | 4 G 10 | 26,0 | 404,0 | 1010,0 | 8 |

| 26022 | 5 G 10 | 28,0 | 508,0 | 1200,0 | 8 |

| 26023 | 4 G 16 | 29,0 | 642,0 | 1300,0 | 6 |

| 26032 | 5 G 16 | 31,5 | 768,0 | 1700,0 | 6 |

| 26024 | 4 G 25 | 35,0 | 1005,0 | 2000,0 | 4 |

| 26025 | 4 G 35 | 37,5 | 1344,0 | 2610,0 | 2 |

| 26026 | 4 G 50 | 44,5 | 2010,0 | 3500,0 | 1 |

| 26027 | 4 G 70 | 49,0 | 2688,0 | 4600,0 | 2/0 |

| 26028 | 4 G 95 | 56,0 | 3648,0 | 6100,0 | 3/0 |