Dây Cáp Điều Khiển Helukabel ROBOFLEX® 2001 / 2001-C | Chính Hãng – Robot Cables – Giá Tốt Nhất

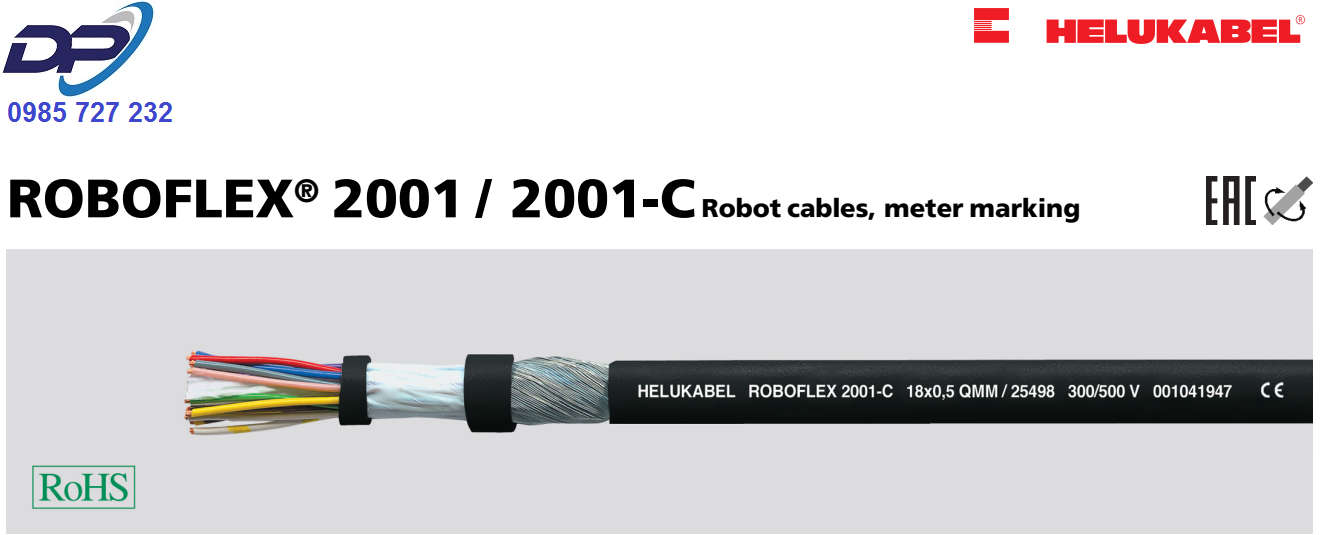

ROBOFLEX® 2001 / 2001-C |

Robot cables, meter marking |

|

Technical data

- Special TPE-E/PUR adapted to

DIN VDE 0250 / DIN VDE 0285-525-1 /

DIN EN 50525-1

Temperature range

flexing -30°C to +80°C

fixed installation -40°C to +80°C - Nominal voltage

up to 0,34 mm² 350 V

(operating peak voltage)

from 0,5 mm² U0/U 300/500 V - Test voltage

up to 0,34 mm² 1,5 kV, 5 minutes

from 0,5 mm² 3,0 kV, 5 minutes - Mutual capacitance

core/core approx. 100 pF/m

core/screen approx. 120 pF/m - Inductance approx.

0,69 mH/km - Minimum bending radius

7,5x cabel Ø

Cable structure

- Bare copper, stranded to DIN VDE 0295

and IEC 60228, fine or extra fine wires,

cl.5 or cl.6, BS 6360 cl.5 or 6, up to

0,34 mm² cl.5, above 0,5 mm² cl.6 - Special core insulation, PP

- Core identification

up to 0,34 mm² acc.to DIN 47100

above 0,5 mm² acc.to DIN VDE 0293

black cores with continuous

white numbering - GN-YE conductor, 3 cores and above

in the outer layer - Cores stranded in layers with

optimal lay length - Special separating foil

- Cable structure C-type, cu-screen of helically

wound, approx. 85-95% coverage - Outher sheath, special polyurethane

- Sheath colour: black (RAL 9005)

- With meter marking

Properties

- High flexibility at low temperatures

- High abrasion resistance

- Loadable under torsion stress ±360°/meter

- Low adhesion

- Resistant to

Microbes and rotting

Oxygene and ozone

Vibrations

UV-radiation - Largely resistant to

Oil and fats resistant

Note

- AWG sizes are approximate equivalent

values. The actual cross section is in mm²

Application

These special robotic control and signal cables specially designed for torsion and bending stresses in robots and connecting handling tools.

EMC = Electromagnetic compatibility

To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

ROBOFLEX® 2001

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 25459 | 7 x 0,25 | 5,8 | 16,8 | 48,0 | 24 |

| 25439 | 12 x 0,25 | 7,6 | 28,8 | 71,0 | 24 |

| 25460 | 25 x 0,25 | 10,6 | 60,0 | 143,0 | 24 |

| 25461 | 2 x 0,34 | 4,0 | 6,6 | 28,0 | 22 |

| 25462 | 3 x 0,34 | 4,0 | 9,8 | 34,0 | 22 |

| 25440 | 7 x 0,34 | 5,7 | 22,8 | 51,0 | 22 |

| 25449 | 12 x 0,34 | 8,3 | 39,2 | 69,0 | 22 |

| 25463 | 12 G 0,5 | 10,4 | 57,8 | 90,0 | 20 |

| 25519 | 16 G 0,5 | 11,6 | 76,8 | 277,0 | 20 |

| 25464 | 18 G 0,5 | 12,7 | 86,4 | 121,0 | 20 |

| 25465 | 25 G 0,5 | 14,2 | 120,0 | 256,0 | 20 |

| 25466 | 4 G 0,75 | 6,0 | 28,8 | 63,0 | 19 |

| 25450 | 7 G 0,75 | 7,9 | 50,4 | 96,0 | 19 |

| 25467 | 12 G 0,75 | 11,5 | 84,4 | 171,0 | 19 |

| 25468 | 14 G 0,75 | 12,8 | 100,8 | 200,0 | 19 |

| 25469 | 2 x 1 | 5,5 | 19,2 | 48,0 | 18 |

| 25470 | 3 G 1 | 6,0 | 29,0 | 60,0 | 18 |

| 25471 | 4 G 1 | 6,3 | 38,4 | 78,0 | 18 |

| 25472 | 7 G 1 | 8,5 | 67,2 | 131,0 | 18 |

| 25473 | 12 G 1 | 12,5 | 115,2 | 216,0 | 18 |

| 25474 | 18 G 1 | 15,4 | 172,8 | 306,0 | 18 |

| 25475 | 25 G 1 | 17,4 | 240,0 | 432,0 | 18 |

| 25476 | 34 G 1 | 21,3 | 326,4 | 569,0 | 18 |

| 25477 | 41 G 1 | 23,2 | 393,6 | 694,0 | 18 |

| 25520 | 3 G 1,5 | 6,9 | 43,2 | 94,0 | 16 |

| 25529 | 4 G 1,5 | 7,9 | 57,6 | 107,0 | 16 |

| 25559 | 5 G 1,5 | 8,6 | 72,0 | 121,0 | 18 |

| 25509 | 8 G 1,5 | 11,1 | 115,2 | 292,0 | 16 |

| 25478 | 12 G 1,5 | 15,5 | 172,8 | 356,0 | 16 |

| 25479 | 18 G 1,5 | 19,3 | 259,2 | 445,0 | 16 |

| 25480 | 25 G 1,5 | 21,8 | 360,0 | 636,0 | 16 |

| 25481 | 3 G 2,5 | 8,4 | 72,0 | 136,0 | 14 |

| 25482 | 4 G 2,5 | 9,1 | 96,0 | 170,0 | 14 |

| 25483 | 3 G 4 | 10,3 | 116,0 | 227,0 | 12 |

| 25530 | 4 G 4 | 11,2 | 153,6 | 261,0 | 12 |

| 25510 | 4 G 6 | 14,1 | 230,4 | 341,0 | 10 |

| 25484 | 3 G 10 | 15,6 | 288,0 | 518,0 | 8 |

| 25485 | 3 G 16 | 18,2 | 460,8 | 722,0 | 6 |

| 25486 | 3 G 25 | 22,9 | 720,0 | 1180,0 | 4 |

| 25487 | 3 G 35 | 26,5 | 1008,0 | 1600,0 | 2 |

ROBOFLEX® 2001-C

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 25539 | 10 x 0,14 | 7,8 | 34,2 | 62,0 | 26 |

| 25488 | 12 x 0,14 | 7,8 | 42,1 | 95,0 | 26 |

| 25489 | 18 x 0,14 | 9,7 | 54,5 | 120,0 | 26 |

| 25490 | 25 x 0,14 | 10,9 | 69,0 | 158,0 | 26 |

| 25491 | 12 x 0,25 | 8,3 | 59,5 | 126,0 | 24 |

| 25492 | 18 x 0,25 | 10,1 | 80,0 | 164,0 | 24 |

| 25493 | 25 x 0,25 | 11,1 | 103,0 | 215,0 | 24 |

| 25494 | 12 x 0,34 | 8,8 | 78,0 | 160,0 | 22 |

| 25495 | 18 x 0,34 | 10,8 | 101,0 | 210,0 | 22 |

| 25496 | 25 x 0,34 | 12,0 | 158,0 | 305,0 | 22 |

| 25497 | 12 G 0,5 | 11,2 | 117,0 | 175,0 | 20 |

| 25498 | 18 G 0,5 | 13,6 | 160,0 | 231,0 | 20 |

| 25499 | 25 G 0,5 | 14,8 | 255,0 | 347,0 | 20 |

| 25500 | 12 G 0,75 | 11,8 | 155,0 | 220,0 | 19 |

| 25501 | 18 G 0,75 | 15,0 | 210,0 | 305,0 | 19 |

| 25502 | 25 G 0,75 | 16,6 | 275,0 | 415,0 | 19 |

| 705462 | 3 G 1 | 6,3 | 76,0 | 90,0 | 18 |

| 25503 | 12 G 1 | 13,0 | 190,0 | 265,0 | 18 |

| 25504 | 18 G 1 | 16,1 | 245,0 | 390,0 | 18 |

| 25505 | 25 G 1 | 18,1 | 345,0 | 540,0 | 18 |

| 25506 | 12 G 1,5 | 16,2 | 260,0 | 345,0 | 16 |

| 25507 | 18 G 1,5 | 20,3 | 370,0 | 485,0 | 16 |

| 25508 | 25 G 1,5 | 22,5 | 498,0 | 710,0 | 16 |