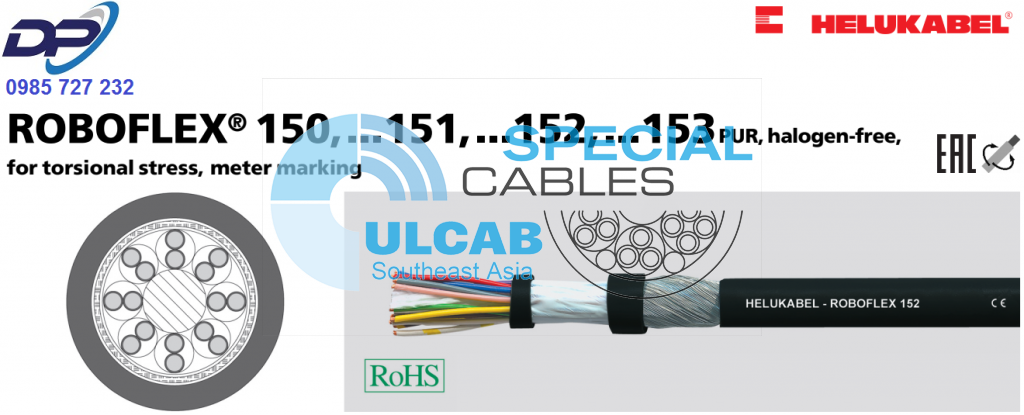

Dây Cáp Điều Khiển Helukabel ROBOFLEX® 150 (screened), Sheath colour grey | Chính Hãng – Robot Cables – Giá Tốt Nhất

ROBOFLEX® 150 |

PUR, halogen-free, for torsional stress, meter marking |

|

Technical data

- Special TPE-E/PUR robot cable

based on DIN VDE 0250 /

DIN VDE 0285-525-1 / DIN EN 50525-1 - Temperature range

flexing -40°C to +80°C - Nominal voltage

up to 0,34 mm² 350 V

from 0,5 mm² U0/U 300/500 V - Test voltage

up to 0,34 mm² 1500 V

from 0,5 mm² 3000 V - Insulation resistance

min. 20 MOhm x km - Max. torsion angle

±360°/metre - Mutual capacitance

core/core approx. 100 pF/m

core/screen approx. 120 pF/m - Minimum bending radius

15x cable Ø

Cable structure

- Bare copper, stranded to DIN VDE 0295 and

IEC 60228, fine or extra fine wires,

cl.5 or cl.6, BS 6360 cl.5 or 6,

up to 0,34 mm² cl.5, above 0,5 mm² cl.6 - TPE-E core insulation

- Black cores continuous white numbering

acc. to DIN VDE 0293 + gnye - Special optimised stranding

- High-grade slide wrapping

- With meter marking

- Tinned copper twist screen

- PUR outer sheath

- Sheath colour: grey (RAL 7001) or black

Part. nos. 77261-77263, 76158, 70561,

77267, 77268, 76165, 76166, 77424

- Core colours DIN 47100

Part no. 71820, 74658, 77264, 75253,

76167

- Construction as above, but 0,5 (1,0) mm²

cores screened with aluminium-coated

polyester foil

Part no. 72214

- Construction as above, but 0,5 mm² pair

screened with tinned twist screen

Part no. 77265, 77266, 77269, 77270

- Construction as above, but 1,0 mm² pair

only, screened with tinned twist screen

Part no. 77469

- Construction as above, but

- 6 cores, 1,5 mm², screened with tinned

twist screen - 4 pairs, 0,25 mm², screened with tinned

twist screen - Sheath colour: orange (RAL 2003)

- With meter marking

Properties

- PUR outer sheath, low adhesion, abrasion

resistant, halogen-free, resistant to UV, oil,

hydrolysis and microbial attack - The smooth, high-grade core insulation,

together with special stranding configuration

and slide wrapping ensure long service life

under combined bending and torsional

stresses

Note

- AWG sizes are approximate equivalent

values. The actual cross section is in mm².

Application

These cables are specially designed for combined torsional and bending stresses. They are employed both for power supply and for the transmission of control and monitoring signals. ROBOFLEX® cables are used in assembly and welding robots, in handling and automation centres, in transport and conveyor equipment, and on turntables and swivel tables. In other words, anywhere where there is no defined cable routing with only alternating bending cycles on a single plane such as in drag chains.

CE = Product conforms with Low-Voltage Directive 2014/35/EU.

Downloads

ROBOFLEX® 150 (screened), Sheath colour grey

| Part no. | No.cores x cross-sec. mm² |

Outer Ø

approx. mm |

Cop. weight kg / km |

Weight

approx. kg / km |

AWG-No. |

|---|---|---|---|---|---|

| 77261 | (12 x 0,25) | 8,3 | 59,5 | 126,0 | 24 |

| 77266 | 23 x 1 + (2 x 1,0) | 17,4 | 262,0 | 473,0 | – |

| 71789 | (4 x 1,5) | 8,9 | 81,7 | 150,0 | 16 |

| 75251 | (4 x 2,5) | 11,2 | 134,0 | 280,0 | 14 |

| 75252 | (4 x 4) | 13,1 | 200,0 | 400,0 | 12 |

| 76157 | (4 x 6) | 15,4 | 286,0 | 550,0 | 10 |

| 77262 | (3 x 2 x 0,14) | 5,8 | 17,0 | 43,0 | 26 |

| 77263 | (4 x 2 x 0,14) | 6,9 | 37,0 | 75,0 | 26 |

| 76158 | (5 x 2 x 0,34) | 9,2 | 65,0 | 116,0 | 22 |

| 70561 | (8 x 2 x 0,34) | 10,2 | 90,0 | 150,0 | 22 |

| 71820 | (4 x 1,5 + (2 x 0,62)) | 10,5 | 106,8 | 195,0 | 16 |

| 74658 | (4 x 1,5 + (2 x 0,5)) | 10,7 | 95,0 | 180,0 | 16 |

| 77264 | (4 x 1,5 + (2 x 1,0)) | 11,1 | 128,0 | 220,0 | 16 |

| 75253 | (4 x 2,5 + (2 x 0,5)) | 12,5 | 180,0 | 270,0 | 14 |

| 72214 | (4 x 4 + (2 x 0,62)) | 13,5 | 260,0 | 340,0 | 12 |

| 76159 | (4 x 4 + (2 x 1,0)) | 14,0 | 237,0 | 350,0 | 12 |

| 76160 | (4 x 6 + (2 x 1,0)) | 16,0 | 341,0 | 500,0 | 10 |

| 77265 | 16 x 1 + (2 x 1,0) | 16,7 | 197,0 | 380,0 | 18 |