Cáp Quang GYXTW HANXIN – Multimode: OM2 OM3 OM4 50/125 µm

OUTDOOR FIBER OPTIC CABLE SPECIFICATION

OM2/OM2+/OM3/OM4- GYXTW 2-24 CORE

OM2+ Multimode Fibre Complies with or exceeds ISO.IEC 11801 OM2 specification IES 60793-2-10 type A1a.1 Optical Fiber

Specification, and TIA/EIA-492AAAB-A detail specification.

OM3/OM4 Multimode Febers comply with or execeed ISO/IEC 11801 OM3/OM4 specification, IEC 60793-2-10 type A1a.2 and

A1a.3 Optical Fibre Specification, and TIA/EIA-492AAAC/492AAAD deatil specification.

Features

Up to 24 fibers

850nm laser-optimized

Extremely refined refractive index profile

Low differential mode delay (DMD)

Low attenuation

Uni tube gel-filled constrcuction for supenor fiber

protection

Corrugated steel tape armor to protect cable from

mechanical damage

Superior geometry, uniformity

Two parallel steel wite or Non-metallic FRP wite

to enhance tensile resistant

UV and moisture-resistant desigs.

Temperature Range

Opeating -400C to +700C

Storago -500C to +700C

Installation -300C to +700C

Bending Radius:

Static 10D

Dynamic 20D

Benefits and Applications

– Data centers

– Storage Area networks

– High performance computing centers

– Central offices

– Local Area Network

– 1&10&40&100 Gb/s Ethernet

– Optimized performance in tighr-buffer cable applications

– High resistance to micro-bending

– Stable performance over a wide range of environmental conditions

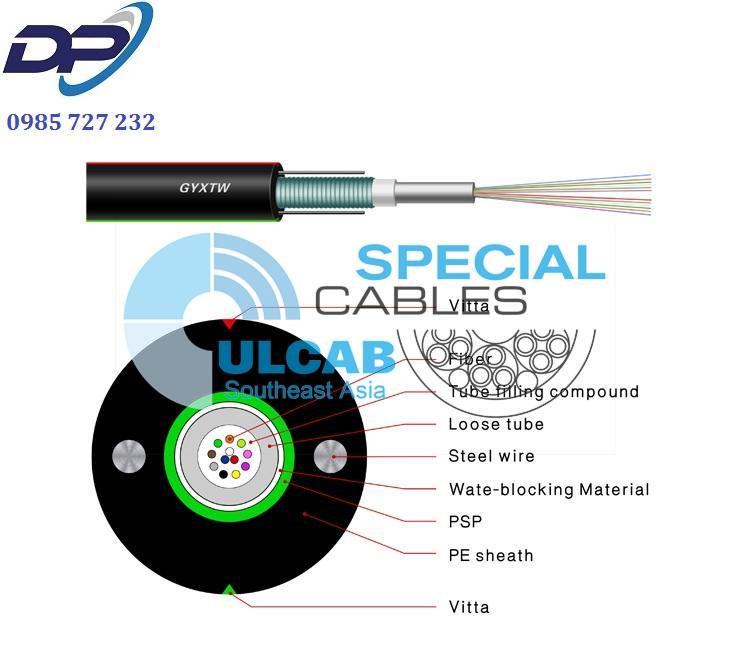

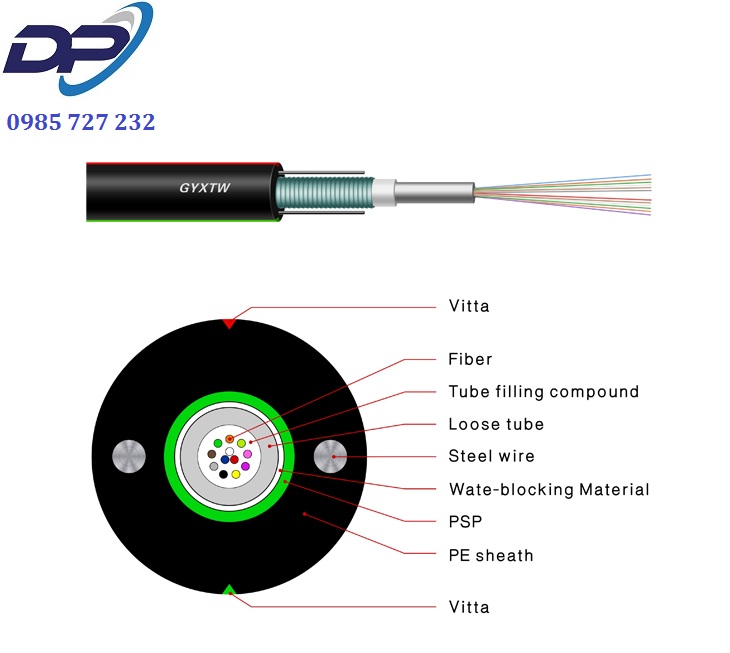

| GYXTW Description – OM2+/OM3/OM4 |

OUTDOOR CABLE |

Product description/ PRODUCT

The fibers,200/250um, are positioned in a loose tube made of a high modulus plastic.The tubes are filled with a water-resistant filling compound. The tube is wrapped with a layer of PSP longitudinally. Between the PSP and the loose tube water-blocking material is applied to keep the cable compact and watertight. Two parallel steel wires are placed at the two sides of the steel tape. The cable is completed with a polyethylene (PE)sheath.

Armored Uni – Tube Single Jacket/Single Armored cable is designed with the filexbility and versatility required for

today’s most demanding installations including direct baried. The metallic armor is used when mechanica protecttion is

Product Features/ PRODUCT

·Good mechanical and temperature performance

·High strength loose tube that is hydrolysis resistant

·Special tube filling compound ensure a critical protection of fiber

·Crush resistance and flexibility

·PSP enhancing moisture-proof

·Two parallel steel wires ensure tensile strength

·PE sheath gives excellent UV protection

·Small diameter, light weight and friendly installation

·Long delivery length

desired.

1. Construction

1.1 :PE jacket

1.2 Parallel steel strength member

1.3 Corrugated steel taps armored (PSP)

1.4 Water blocking tapsPBT LooseTube

1.5 Jelly core fibers

Product standard/ PRODUCT

GYXTW cable complies with Standard YD/T 769-2010

| Characteristcs | Conditions | Specified Values | Units |

| Geomery Characteristics | |||

| Core Diameter | 50±2.5 | (µm) | |

| Core Non-Circularity | ≤ 50 | (%) | |

| Cladding Diameter | 125.0±1.0 | (µm) | |

| Cladding Non-Circuarity | ≤0.1 | (%) | |

| Coating Diameter | 245±7 | (µm) | |

| Coating/Cladding Concentricity Error | ≤ 10.0 | (µm) | |

| Coating Non-Circularity | ≤ 6.0 | (%) | |

| Core/Cladding Concentricity Error | ≤ 1.0 | (µm) | |

| Delivery Length | Up to 8.8 | (km.reel) | |

| Optical Characteristics | |||

| Attenuation | 850nm 850nm |

≤ 2.4 ≤ 0.6 |

(dB/km) (dB/km) |

| OM2+/OM3/OM4 | |||

| Overfilled Modal Bandwidth | 850nm 1300nm |

≥ 700/≥1500/≥3500 ≥ 700/≥500/≥500 |

(MHz-km) (MHz-km) |

| Effective Modal Bandwidth | 850nm | ≥ 950/≥2000/≥4700 | (MHz-km) |

| Application support distance on | |||

| 40&100 Gigabit Ethernet | 850nm | -/100/150 | (m) |

| 10GBASE-SR | 850nm | 150/300/550 | (m) |

| 1000BASE-SX | 850nm | 750/1000/1100 | (m) |

| DMD Specification | Compliant with and more stringent than the requirements of IEC 60793-2-10 | ||

| Numberical Aperture | 0.200±0.015 | ||

| Group Refractive Index | 850nm 1300nm |

1.482 1.477 |

|

| Zero Dispersion Wavelength, λo | 1295-1340 | (nm) | |

| Zero Dispersion Slope, So | 1295nm≤ λo<1310nm 1310nm ≤λo≤1340nm |

≤0.105 ≤0.000375(1590- λo) |

(ps/nm2-km) (ps/nm2-km) |

| Macrobending Loss | |||

| 100 Turns @37.5mm Radius | 850nm 1300nm |

≤0.50 ≤0.50 |

(dB) (dB) |

| 2 Turns @15mm Radius | 850nm 1300nm |

≤1.0 ≤1.0 |

(dB) (dB) |

| Backscatter Characteristics | |||

| Step ( Mean of Bidirectional Measurement) |

1300nm | ≤0.10 | (dB) |

| Irregularities Over Fibre Length and Point Discontinuity |

1300nm | ≤0.10 | (dB) |

| Attenuation Uniformity | 1300nm | ≤0.08 | (dB/km) |

| Environmental Characteristtics | |||

| Temperature Cycling | -60oC to +85 oC | ≤0.10 | (dB/km) |

| Temperature-Humidity Cycling | -10oC to +85 oC, 4% to 98%RH |

≤1.0 | (dB/km) |

| Water Inmmersion | 23 oC, 30 days | ≤1.0 | (dB/km) |

| Dry Heat | 85 oC, 30 days | ≤1.0 | (dB/km) |

| Damp Heat | 85 oC, 85% RH, 30 days | ≤1.0 | (dB/km) |

| Mechanical Specification | |||

| Proof test | ≥9.0 ≥1.0 ≥100 |

( N) (%) (kpsi) |

|

| Coating Strip Force | Typical average force Peck force |

1.5 ≥ 1.3 ≤ 8.9 |

(N) (N) |

| Dynamic Stress Corrosion Susceptibulity Parameter ( nd, Typical) |

27 | ||

Optical Characteristics/ PRODUCT

|

|

G.652 |

G.655 |

50/125μm |

62.5/125μm |

|

|

Attenuation |

@850nm |

|

|

≤3.0dB/km |

≤3.0dB/km |

|

@1300nm |

|

|

≤1.0dB/km |

≤1.0dB/km |

|

|

@1310nm |

≤0.36dB/km |

— |

|

|

|

|

@1550nm |

≤0.22dB/km |

≤0.23dB/km |

|

|

|

|

Bandwidth (Class A) |

@850 |

|

|

≥500MHZ·km |

≥500MHZ·km |

|

@1300 |

|

|

≥1000MHZ·km |

≥600MHZ·km |

|

|

Numerical Aperture |

|

|

|

0.200±0.015NA |

0.275±0.015NA |

|

Cable Cut-off Wavelength λcc |

≤1260nm |

≤1480nm |

|

|

|

Technical Parameters/ PRODUCT

|

Cable Type |

Fiber Count |

Cable Diameter |

Cable Weight |

Tensile Strength |

Crush Resistance |

Bending Radius |

|

GYXTW-2~12 |

2~12 |

9.0 |

85 |

600/1000 |

500/1500 |

15D/30D |

|

GYXTW-14~24 |

14~24 |

9.0 |

85 |

600/3000 |

1000/3000 |

15D/30D |

|

GYXTW-2~12 |

2~12 |

10.0 |

105 |

1000/3000 |

1000/3000 |

15D/30D |

|

GYXTW-14~24 |

14~24 |

10.0 |

105 |

1000/3000 |

1000/3000 |

15D/30D |

|

GYXTW-26~36 |

26~36 |

14.0 |

190 |

1000/3000 |

1000/3000 |

15D/30D |

|

GYXTW-38~48 |

38~48 |

15.0 |

216 |

1000/3000 |

1000/3000 |

15D/30D |

Storage/Operating Temperature : -40℃ to + 70℃