Dây Cáp LAPP KABEL ÖLFLEX® POWER MULTI | Chính Hãng – Giá Tốt Nhất

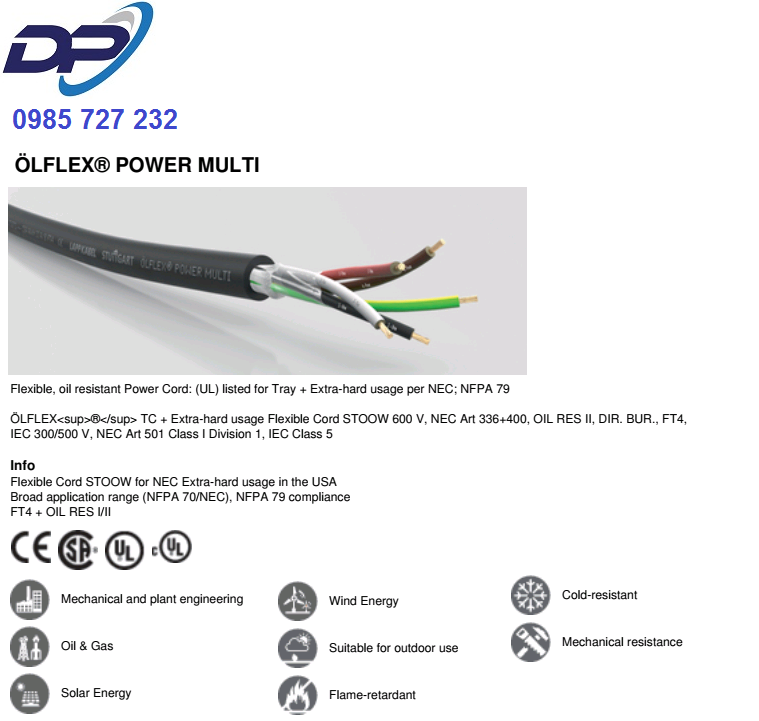

ÖLFLEX® POWER MULTI

Flexible, oil resistant Power Cord: (UL) listed for Tray + Extra-hard usage per NEC; NFPA 79

ÖLFLEX® TC + Extra-hard usage Flexible Cord STOOW 600 V, NEC Art 336+400, OIL RES II, DIR. BUR., FT4, IEC 300/500 V, NEC Art 501 Class I Division 1, IEC Class 5

- Flexible Cord STOOW for NEC Extra-hard usage in the USA

- Broad application range (NFPA 70/NEC), NFPA 79 compliance

- FT4 + OIL RES I/II

Benefits

- Suitability for different operation types and locations in the USA as per NFPA/ NEC under one LAPP part number, thanks to UL listings (UL) STOOW and (UL) TC, resp. TC-ER, as well as thanks to design and characteristics associated with these listings

- Apart from unprotected laying on tray in the USA thanks to TC(-ER) listing: …further, normatively specified, unprotected wiring methods in the USA per application related NEC Articles, thanks to (UL) listing STOOW/ Extra-hard usage Flexible Cord

Application range

- Industrial machinery, plant engineering in the USA

- Unprotected 600V operation on cable tray in the USA, incl. 6 ft. Exposed Run laying sections for version with at least 3 conductors

- As per Article 400 of NEC/ NFPA 70: General Uses Permitted in the USA and General Uses Not Permitted to the overall group of Flexible Cords and Flexible Cables acc. to UL 62;

Operating bids and limitations for Flexible Cords in special applications acc. to further NEC Articles, such as 501 (Class I Locations), 422 (Appliances), or 520 (specific locations for play and production of entertainment), etc. - Further, typical locations in the USA, as specified by respective US installation standardization (e.g., NEC/ NFPA 70): Power cord for equipment, paint booths, appliances, factory installations (branch circuit), any power hook-up in the plant, for harnessed power connecting or extension cord set assemblies

- In hazardous locations in the USA, as per Chapter 5 of NEC/ NFPA 70: Classes I thru III, Divisions 1 and 2 each, plus intrinsically safe circuits, taking account of:

– Provisions on cable design, cable type, installation, application in NEC Chapter 5 (esp.: Articles 500 thru 504);

– This cable’s design, approvals, component identification

Product features

- Highly flame retardant FT4

- Highly oil resistant OIL RES I/II

- Tested sunlight resistant per UL 1277, UL 62, UL 2556 in terms of UV resistance

- Tested for unprotected, direct burial in the USA per UL 1277

Norm references / Approvals

- Certified by UL per UL 1277 for TC 600V use in the USA, subject to individual third-party inspection: Generally UL Type TC (Tray Cable), and for at least 3 or more conductors TC-ER (Tray Cable for Exposed Run) in addition [UL CCN: QPOR; UL File No.: E171371]

- Certified by UL per UL 62 for STOOW use in the USA, subject to individual third-party inspection: UL Type STOOW (Extra-hard usage Flexible Cord) [UL CCN: ZJCZ; UL File No.: E146118]

- Certified by UL per CSA C22.2 No. 239, and CSA C22.2 No. 230 for possible CIC/TC use in Canada, subject to individual third-party inspection: c(UL) CIC/TC FT4 [UL CCN: QPOR7; UL File No.: E171371]

- Certified by UL per CSA C22.2 No. 49 for STOOW use in Canada, subject to individual third-party inspection: c(UL) STOOW [UL CCN: ZJCZ7; UL File No.: E146118]

- Certified by CSA per CSA C22.2 No. 210 for AWM use in Canada, subject to individual third-party inspection: CSA AWM II A/B FT4

Product Make-up

- Fine-wire strand made of bare copper wires

- Specially formulated PVC insulation

- Durable, black sheath made of specially formulated thermoplastic polymer for improved service life

Classification ETIM 5

- ETIM 5.0 Class-ID: EC001578

- ETIM 5.0 Class-Description: Flexible cable

Classification ETIM 6

- ETIM 6.0 Class-ID: EC001578

- ETIM 6.0 Class-Description: Flexible cable

Core identification code

- – Coloured conductors with numbers, plus ground in green/yellow (30 % stripe width);

– For 2-conductor cable only: No green/ yellow ground

– Example 3 conductors:

BLACK conductor: “1 – ONE”

WHITE conductor: “2 – TWO”

GREEN/YELLOW conductor: No Numbers - – Colour code:

2C: Black, White

3C: Black, White, Green-Yellow

4C: Black, White, Red, Green-Yellow

5C: Black, White, Red, Brown, Green-Yellow

6C or more: Black with white numbers, except for the included Green-Yellow ground

Conductor stranding

- Fine wire according to DIN EN 60228 (VDE 0295), class 5 / IEC 60228 class 5

Minimum bending radius

- Installation: 4 x outer diameter

Nominal voltage

- UL/CSA TC/STOOW: 600 V

- IEC U0/U: 300/500 V

Test voltage

- 2000 V

Protective conductor

- G = with GN-YE protective conductor

Temperature range

- UL/CSA TC: -25°C to +90°C;

- Occasional flexing/ North America: -25°C to +105°C;

Fixed installation/ North America: -40°C to 105°C

| Article number | Number of cores and mm² per conductor |

Outer diameter [mm] | Copper index (kg/km) | Weight (kg/km) |

| 611803 | 3 G 1.0 | 9.4 | 29.763 | 92 |

| 611804 | 4 G 1.0 | 10.1 | 38.692 | 106 |

| 611805 | 5 G 1.0 | 12 | 49.109 | 122 |

| 611812 | 12 G 1.0 | 16.1 | 115.195 | 260 |

| 611603 | 3 G 1.5 | 10.1 | 43.157 | 110 |

| 611604 | 4 G 1.5 | 10.9 | 58.038 | 128 |

| 611605 | 5 G 1.5 | 12.9 | 72.027 | 153 |

| 611612 | 12 G 1.5 | 18.3 | 172.775 | 330 |

| 611618 | 18 G 1.5 | 20.9 | 259.237 | 440 |

| 611625 | 25 G 1.5 | 24.5 | 360.134 | 598 |

| 611403 | 3 G 2.5 | 13.8 | 72.027 | 137 |

| 611404 | 4 G 2.5 | 14.8 | 96.73 | 167 |

| 611405 | 5 G 2.5 | 16.8 | 120.541 | 198 |

| 611203 | 3 G 4.0 | 16 | 115.183 | 188 |

| 611205 | 5 G 4.0 | 18.8 | 191.972 | 286 |

| 611003 | 3 G 6.0 | 17.2 | 172.775 | 342 |

| 611004 | 4 G 6.0 | 18.6 | 230.664 | 402 |

| 610803 | 3 G 10.0 | 21.3 | 288.702 | 641 |

| 610804 | 4 G 10.0 | 24 | 383.944 | 844 |