“KVC-43BX” Cáp Tín Hiệu Điều Khiển KURAMO Chính Hãng – Giá Tốt Nhất

Thương hiệu/ Brand-name: Kuramo Cable

Mã hàng/ Part number: KVC-43BX

Tiết diện lõi dẫn/ Conductor size: 0.24㎟ | 0.38㎟ | 0.5㎟

Số lõi/ Pair Number: 1P – 2P – 3P – 4P – 5P – 6P – 8P – 10P – 12P – 15P – 20P – 25P – 30P – 2P+1 – 3P+1 – 2 Cores – 3 Cores – 4 Cores – 5 Cores – 6 Cores – 7 Cores – 8 Cores – 10 Cores – 12 Cores – 16 Cores – 20 Cores – 24 Cores – 30 Cores

Xuất xứ/ Origin: Nhật Bản/ Japan

Vỏ ngoài / Sheath: Vỏ PVC Chống Dầu và chịu nhiệt/ Oil and heat resistant PVC (black)

Vỏ ngoài / Sheath color: Mầu đen / Black

Nhiệt độ hoạt động tối đa/ Temperature rating: -30 to 75℃

Mục đích sử dụng: Wiring to cable carriers (low speed)

Đặc tính nổi bật: Dây dẫn bện, Khả năng chống uốn.

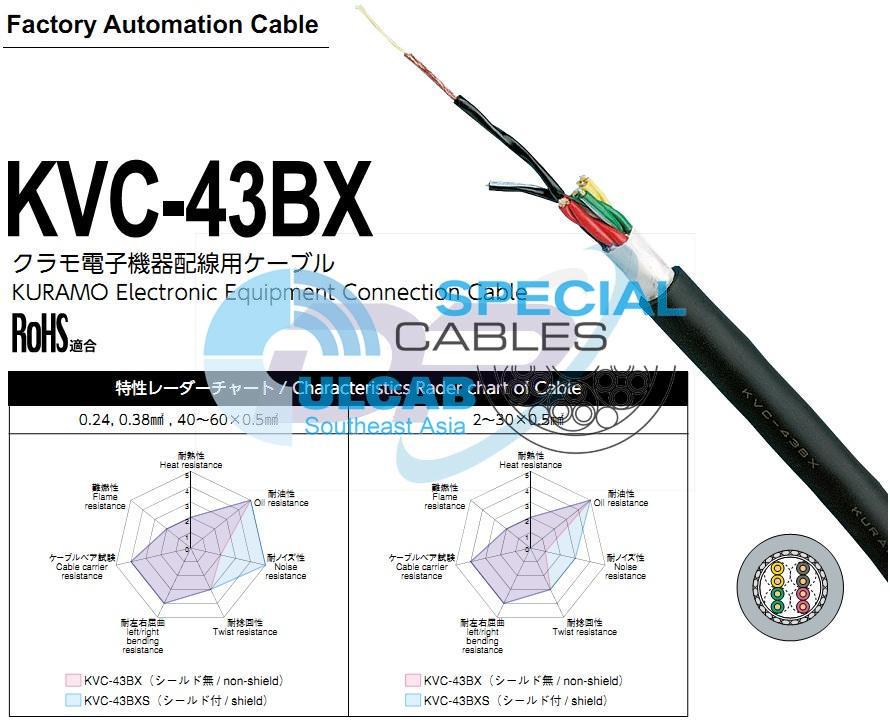

Factory Automation Cable

KVC-43BX

クラモ電子機器配線用ケーブル

KURAMO Electronic Equipment Connection Cable

用 途 / Use

■ケーブルベアへの配線(低速用)

Wiring to cable carriers (low speed)

■耐ノイズ性要求箇所への配線(シールド付タイプ:KVC-43BXS)

Wiring to the portion requiring noise resistance(Shielded type:KVC-43BXS)

特 長 / Features

■耐ノイズ性(シールド付タイプ:KVC-43BXS)

Noise resistance(Shielded type:KVC-43BXS)

■編組導体・耐屈曲性

Braided conductor, bending resistance

■シースつや消し

Sheath mat type

使用温度範囲 / Temperature range

■固定時 / Fixed:-30 〜 75℃ ※

■可動時 / Flexing:0 〜 75℃

※ 0℃以下でご使用の際は、衝撃・屈曲・振動等の外的力が加わらないようにしてください。

If you use it in temperature less than 0℃ , you should be careful about shocks, flexure, vibration and so on.

曲げ半径 / Bending radius

■固定時:ケーブル外径の 4 倍以上推奨

Fixed:4 times or more of the cable diameter

■可動時:ケーブル外径の 7.5 倍以上推奨

Flexing:7.5 times or more of the cable diameter

RoHS 指令 / RoHS Directive

■適合 / Conformity

■テクニカルデータ / Technical data

| ケーブルタイプ / Cable designation | 国内 / JAPAN |

| 適用サイズ / Adaptation size | −※ |

| 定格電圧 / Voltage rating | − |

| 定格温度 / Temperature rating | 75℃ |

| 試験電圧 / Test voltage | AC 1000V・1min |

| 難燃性 / Flame resistance | 60°傾斜 / 60°Angle |

| 適用規格 / Adaptation standard | −※ |

※ KVC-43BX,KVC-43BXS は電気用品安全法が適用されませんので、信号及び通信回路などの弱電流回路にご使用下さい。

KVC-43BX and KVC-43BXS are excluded to “Electrical Appliance and Material Safety Law”, for this reason, those cable should be used for cable connection to signal and communication circuits and other weak current elctrical circuits JAPAN.

< 0.24㎟ , 0.38㎟>

■構造概略 / Construction

| 品名 / Code | KVC-43BX |

| 導体 / Conductor | 軟銅編組線(中心補強紐入り)/ Annealed braided copper (containing reinforcement cord at its center) |

| 絶縁体 / Insulation | 耐熱性ビニル混合物 / Heat resistant PVC |

| 対より / Conductor stranding | 線心を対より / Twisted pair |

| より合わせ / Pair strand | 対より線心を円形により合わせ / Strands of twisted pair in circular form |

| テープ / Tape | 4 心(2P)以上はテープを重ね巻き Tape wrap around cores if conductors are 4 (2P) or more |

| シールド / Shield | − |

| シース / Sheath | 耐油・耐熱性ビニル混合物(黒色)/ Oil and heat resistant PVC (black) |

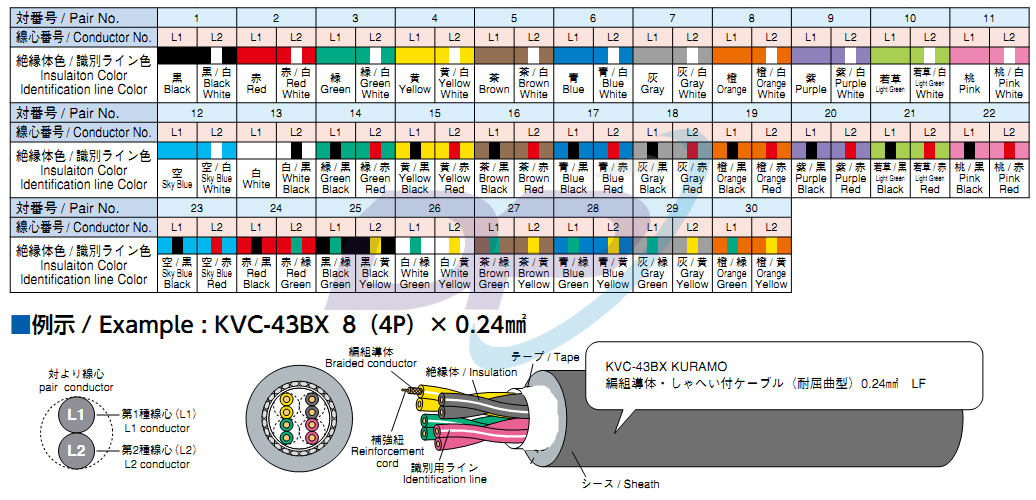

■線心識別/ Conductors identification

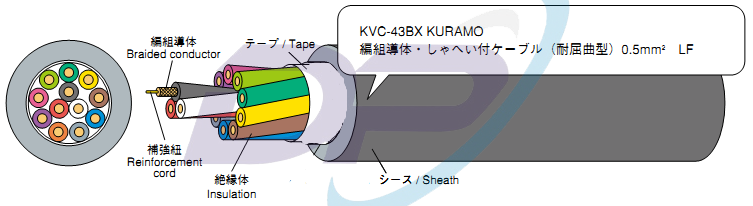

< 0.5㎟>

■構造概略 / Construction

| 品名 / Code | KVC-43BX |

| 導体 / Conductor | 軟銅編組線(中心補強紐入り)/ Annealed braided copper (containing reinforcement cord at its center) |

| 絶縁体 / Insulation | 耐熱性ビニル混合物 / Heat resistant PVC |

| 対より / Conductor stranding | 線心を対より(40 心以上に適用)/ Twisted pair (Applicable to 40 conductors or more) |

| より合わせ / Pair strand | 線心を円形により合わせ / Circular |

| テープ / Tape | 5 心以上はテープを重ね巻き Tape wrap around cores if conductors are 5 or more |

| シールド / Shield | − |

| シース / Sheath | 耐油・耐熱性ビニル混合物(黒色)/ Oil and heat resistant PVC (black) |

■線心識別/ Conductors identification

| 線心数 / No. of conductors | 線心識別方式 / Conductors identification |

| 12 心以下 / 12 or less | 絶縁体着色方式 Identification by color (黒、白、赤、緑、黄、茶、青、灰、橙、紫、桃、若草の順) ( in order of black, white, red, green, yellow, brown, blue, gray, orange, purple, pink and light green ) |

| 13 心以上 / 13 or more | ナンバリング No. 方式 Identification by number (白色絶縁体表面に 1、2、3、4・・・を連続表示) ( marked on white insulation surface in order of 1, 2, 3, 4 and so on ) |

■例示/ Example : KVC-43BX 12 × 0.5㎟

■構造表/ Construction table

| 導体 / Conductor | 絶縁 / Insulation | 心数 Number of conductors |

在庫 / Stocks | シールド無し / Non-shield | 電気特性 / Electrical characteristics | ||||

| 公称断面積 Nominal cross sectional area |

外径(約㎜) Diameter (Approx.㎜) 構成 〈Construction〉 |

外径(約㎜) Diameter (Approx.㎜) |

シールド無 Non-shield |

シース外径(約㎜) Sheath diameter (Approx.㎜) |

概算重量 Approx.weight (kg/ km) |

許容電流 Allowable ampacity (A) |

導体抵抗 Conductor resistance 20℃(Ω / ㎞) |

絶縁抵抗 Insulation resistance 20℃(M Ω㎞) |

|

| 0.24㎟ | 0.9 <48/0.08> |

1.5 | 2 (1P) | ○ | 5.1 | 27 | 6 | 93.3 以下 (Max 93.3) |

50 以上 (Min 50) |

| 3 | ○ | 5.3 | 35 | 5 | |||||

| 4 (2P) | ○ | 7.5 | 55 | 5 | |||||

| 5 (2P+1) | 7.6 | 60 | 5 | ||||||

| 6 (3P) | ○ | 7.9 | 65 | 5 | |||||

| 7 (3P+1) | 8.0 | 70 | 4 | ||||||

| 8 (4P) | ○ | 8.5 | 80 | 4 | |||||

| 10 (5P) | ○ | 9.4 | 95 | 4 | |||||

| 12 (6P) | ○ | 10.0 | 110 | 4 | |||||

| 16 (8P) | ○ | 11.5 | 135 | 3 | |||||

| 20 (10P) | ○ | 12.0 | 160 | 3 | |||||

| 24 (12P) | ○ | 12.5 | 180 | 3 | |||||

| 30 (15P) | ○ | 14.0 | 220 | 3 | |||||

| 40 (20P) | ○ | 15.5 | 275 | 2 | |||||

| 50 (25P) | 17.5 | 335 | 2 | ||||||

| 60 (30P) | 19.0 | 390 | 2 | ||||||

| 0.38㎟ | 1.1 <48/0.10> |

1.8 | 2 (1P) | ○ | 5.7 | 40 | 8 | 59.7 以下 (Max 59.7) |

50 以上 (Min 50) |

| 3 | ○ | 6.2 | 45 | 7 | |||||

| 4 (2P) | ○ | 8.6 | 75 | 7 | |||||

| 5 (2P+1) | 8.7 | 80 | 7 | ||||||

| 6 (3P) | ○ | 9.1 | 90 | 6 | |||||

| 7 (3P+1) | 9.2 | 95 | 6 | ||||||

| 8 (4P) | ○ | 10.0 | 115 | 6 | |||||

| 10 (5P) | ○ | 11.0 | 125 | 5 | |||||

| 12 (6P) | ○ | 12.0 | 150 | 5 | |||||

| 16 (8P) | ○ | 13.5 | 195 | 4 | |||||

| 20 (10P) | ○ | 14.5 | 225 | 4 | |||||

| 24 (12P) | ○ | 15.0 | 250 | 4 | |||||

| 30 (15P) | 16.0 | 305 | 3 | ||||||

| 40 (20P) | 18.5 | 390 | 3 | ||||||

| 50 (25P) | 20.5 | 475 | 3 | ||||||

| 60 (30P) | 22.0 | 555 | 3 | ||||||

| 0.5㎟ | 1.3 <64/0.10> |

2.1 | 2 | ○ | 6.6 | 45 | 10 | 44.8 以下 (Max 44.8) |

50 以上 (Min 50) |

| 3 | ○ | 7.1 | 60 | 9 | |||||

| 4 | ○ | 7.6 | 70 | 8 | |||||

| 5 | 8.6 | 90 | 8 | ||||||

| 6 | ○ | 9.2 | 100 | 7 | |||||

| 7 | 9.8 | 115 | 7 | ||||||

| 8 | ○ | 10.5 | 130 | 7 | |||||

| 10 | ○ | 11.5 | 155 | 6 | |||||

| 12 | ○ | 11.5 | 170 | 6 | |||||

| 16 | ○ | 13.0 | 210 | 5 | |||||

| 20 | ○ | 14.5 | 265 | 5 | |||||

| 24 | ○ | 16.0 | 305 | 5 | |||||

| 30 | ○ | 17.0 | 365 | 4 | |||||

| 40 (20P) | ○ | 21.5 | 500 | 4 | |||||

| 50 (25P) | ○ | 23.5 | 610 | 4 | |||||

| 60 (30P) | 25.0 | 720 | 3 | ||||||

○は在庫品です。/ ○ : Stocks

■許容電流について/ Allowable ampacity

・許容電流値は周囲温度 30℃、空中 1 条敷設時の計算値を示し、保証値ではありません。

Allowable ampacity (A) for cable is based on calculation under aerial one-cable and temperature at 30℃, not repressenting a guaranteed value.

・周囲温度 30℃以上の場合は、次の電流減少係数を表の値に乗じて下さい。

Allowable ampacity cable at ambient temperature abobe 30℃ is to be determined by multiplying the current value by the appropriate current reduction factorin

the following table1.

・許容電流の値は、JCS016 8 により算出した値であって、保証値ではありません。

The allowable ampacity for cable are the calculated by JCS0168, but not guaranteed.

JCS0168…日本電線工業会規格 “33kV 以下電力ケーブルの許容電流計算”

“Calculation of the current rating of power cables for rated voltage up to and including 33kV”

■表 電流減少係数 / Table1 Current reduction factors

| 周囲温度 / Ambient temperature (℃) | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 |

| 電流減少係数 / Current reduction factors | 1.00 | 0.97 | 0.93 | 0.89 | 0.86 | 0.82 | 0.77 | 0.73 | 0.68 |

■編組導体の端末処理 / Termination of Braided Conductor

編組導体の中心には導体補強紐が挿入されています。端末加工後の導体補強のため、端末加工時にこの補強紐を取り除かないで、処

理して下さい。

The cable’s conductor is designed with a reinforcement cord inserted into its center. Therefore, when terminating the conductor, take care to leave the reinforcement cord unremoved to prevent it from losing its conductor reinforcement effect.

■切 断 / Cord cutting

鋭利なハサミで、瞬時に切断して下さい。(補強紐は、ニッパーなどでは完全に切断できません。)

When cutting the cord, use sharp scissors to achieve its instantaneous complete cutting (which cannot be achieved with nippers or other similar tools).

■端末処理方法 / Conductor terminating

圧着端子法:補強紐を取り除かないで、そのまま圧着端子で止めて下さい。

Crimping: When terminating the conductor by crimping, crimp the terminal with the reinforcement cord left unremoved from it.

半田付け法: 補強紐を取り除かないで、そのまま半田付けして下さい。(補強紐は熱に強いので、溶融又は収縮しません。)

Soldering: When terminating the conductor by soldering, solder the terminal with the reinforcement cord left unremoved from it (because the cord is heat resistant, not melting or shrinking during the soldering process).

本製品は編組導体を採用しており、通常の導体外径より大きくなっております。

Conductor of KVC-43BX and KVC-43BXS are larger than conductors of regular KVC cables, because those conductors use “Annealed braided copper”.

圧着端子など加工の際には導体外径等をご確認下さい。

Please check a conductor diameter etc. , if crimping the terminal.